User’s Manual

Model: PW 302/502/802

TOPENS Website

TOPENS Website

http://www.topenstool.com/

★ Please read and follow all warnings, precautions, and instructions before installation and use.

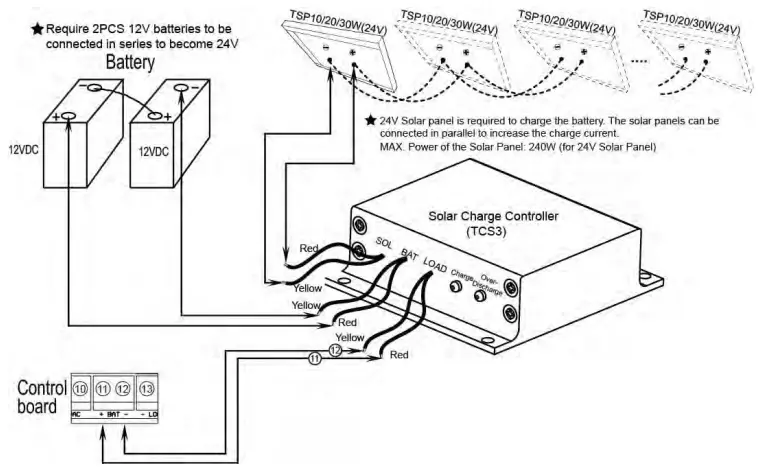

★ The gate opener could be powered by either the 24VDC AC-DC power supply which is included in the package or 2 PCS 12VDC batteries (connected in series, at least 12AH, NOT INCLUDED) which can be charged by a solar panel.

★ Never connect the solar panel to the control board directly to charge the battery.

★ Periodic checks of the opener are required to ensure safe operation.

★ Save this manual.

Ask for OPENS help by E-mail or phone anytime.

Ask for OPENS help by E-mail or phone anytime.

Safety Installation Information

- READ and FOLLOW all instructions.

- The gate opener is intended for use with Class I vehicular swing gates. Class I denotes vehicular gate opener (or system) dwellings, or a garage or parking area associated therewith. Install the gate opener only when the opener is appropriate for the construction and the usage class of the gate.

- Gate opening system designers, installers, and users must take into account the possible hazards associated with each individual application. Improperly designed, installed or maintained systems can create risks for the ser as well as the bystander. Gate system design and installation must reduce public exposure to potential hazards. All exposed pinch points must be eliminated or guarded.

- A gate opener can create high levels of force during normal operation. Therefore, safety features must be incorporated into every installation. Specific safety features include safety sensors.

- The gate must be properly installed and work freely in both directions prior to the installation of the gate opener.

- The gate must be installed in a location so that enough clearance is provided between the gate and adjacent structure when opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

- The opener is intended for use only on gates used for vehicles. Pedestrians must be supplied with a separate access opening. The pedestrian access opening shall be designed to promote pedestrian usage. The pedestrian access shall be located such that persons will not come in contact with the moving vehicular gate.

- Pedestrians should never cross the pathway of a moving gate. The gate opener is not acceptable for use on any pedestrian gate. Pedestrians must be supplied with separate pedestrian access.

- For an installation utilizing non-contact sensors (safety sensors), see the product manual on the placement of non-contact sensors (safety sensors) for each type of application.a. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the safety sensor while the gate is still moving.

b. One or more non-contact sensors (safety sensors) shall be located where the risk of entrapment of obstruction exists, such as the perimeter reachable by a moving gate or barrier. - Never mount any device that operates the gate opener where the user can reach over, under, around, or through the gate to operate the controls. Controls are to be placed at least 6’ (1.8m) from any part of the moving gate.

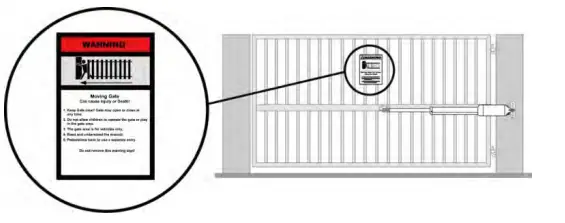

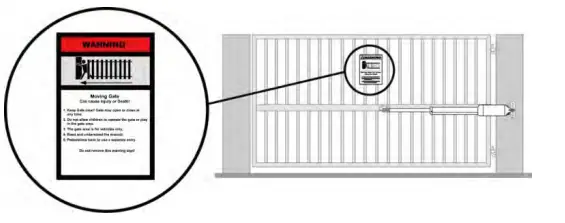

- Each gate opener is provided with two safety warning placards. The placards are to be installed on the front and back of the gate where they are plainly visible. The placards may be mounted using cable ties through the four holes provided on each placard. All warning signs and placards must be installed where visible in the area of the gate.

- To AVOID damaging gas, power, or other underground utility lines, contact underground utility locating companies BEFORE digging. SAVE INSTRUCTION.

- Do not permit children to play on or around the gate and keep all controls out of their reach.

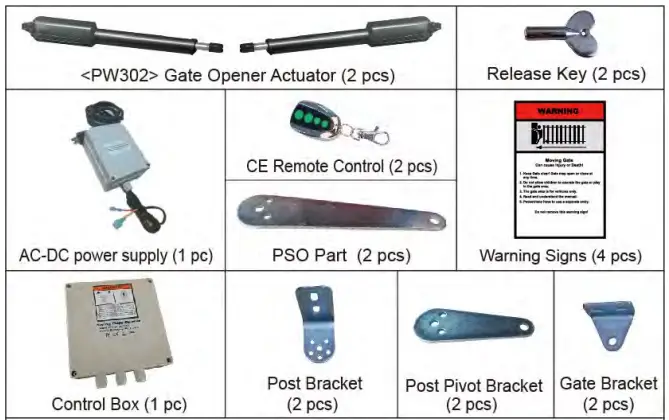

PW302 Parts List

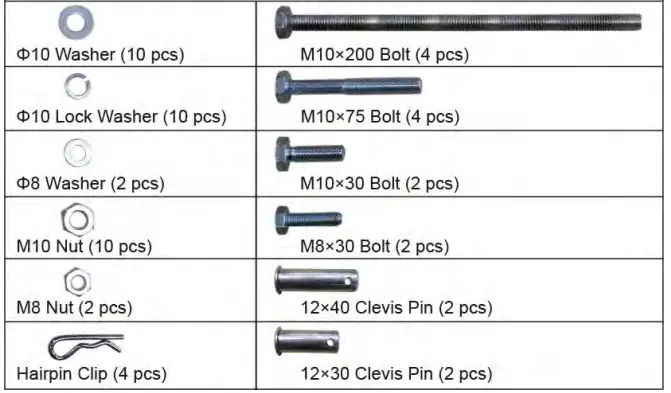

Hardware

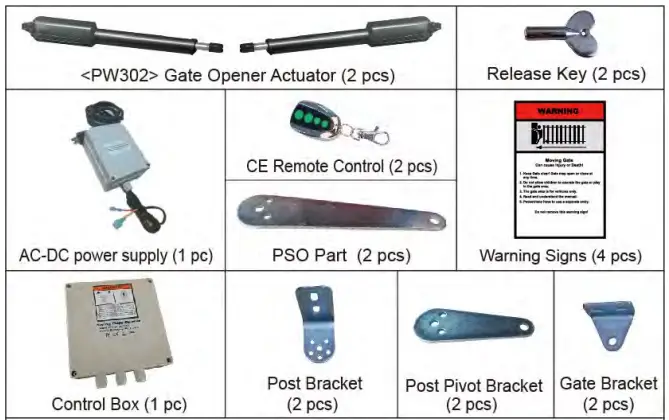

PW502/PW802 Parts List

Hardware

Accessories Parts (Included in some models, refers to the actual package)

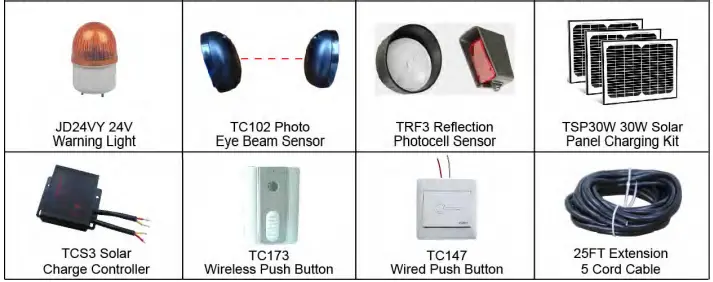

Optional Accessories Parts List (Available at TOPENS Store)

Tools Needed:

- Power Drill

- Tape Measure

- Open End Wrenches – 14# &17# or Adjustable Wrenches

- Wire Strippers ·C-Clamps – small, medium, and large

- Level

- Hacksaw or Heavy Duty Bolt Cutters

- Phillips Screwdriver ·An extra person will be helpful

Technical Specifications & Features

| Specifications | |||

| PW302 | PW502 | PW802 | |

| Input: | 100-240V~ 50/60Hz | ||

| Motor voltage: | 24VDC | ||

| Power: | 2×30W | 2×50W | 2×80W |

| Current: | 1.5A | 2A | 3A |

| Actuator speed: | 16mm/s (0.6 in/s ) | ||

| Max. actuator travel: | 385mm (15.2 in) | ||

| Ambient Temperature: | 20℃~ + 50℃ (-4°F to 122°F) | ||

| Protection class: | IP44 | ||

Features:

- Soft start and soft stop

- Emergency release key in case of power failure

- Fast selecting push/pull to open

- Stop in case of obstruction during gate opening.

- Reverse in case of obstruction during gate closing.

- Built-in adjustable auto-close (3-120 seconds)

- Built in max. Motor running time (MRT) for multiple safety protection (40 seconds)

- Reliable electromagnetism limit for easy adjustment

- Can be equipped with a wide range of accessories

- Adjustable opening/closing interval between master and slave gate

- Easy to install, and minimum maintenance requirement

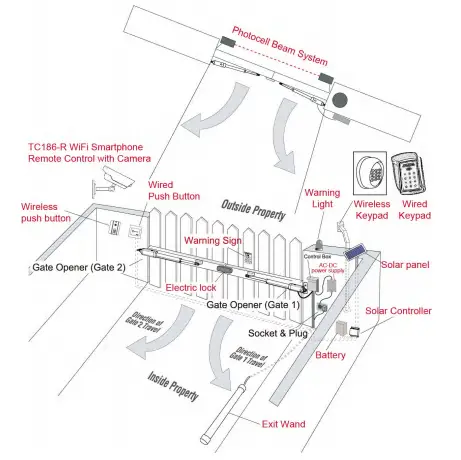

Installation Overview

Preparation for Installation

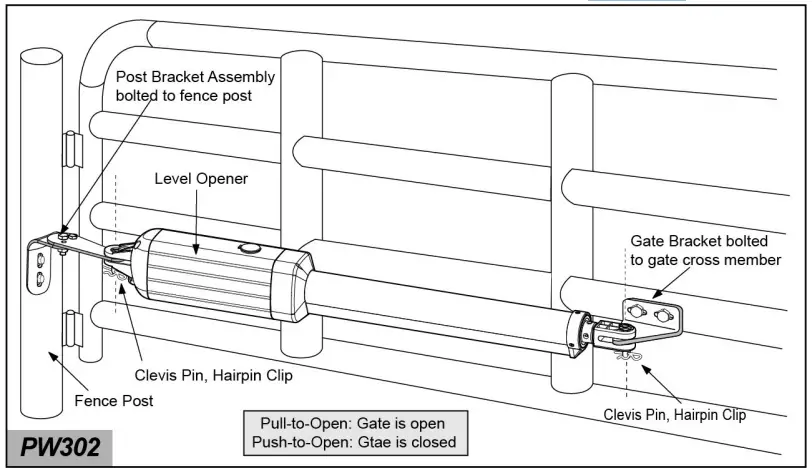

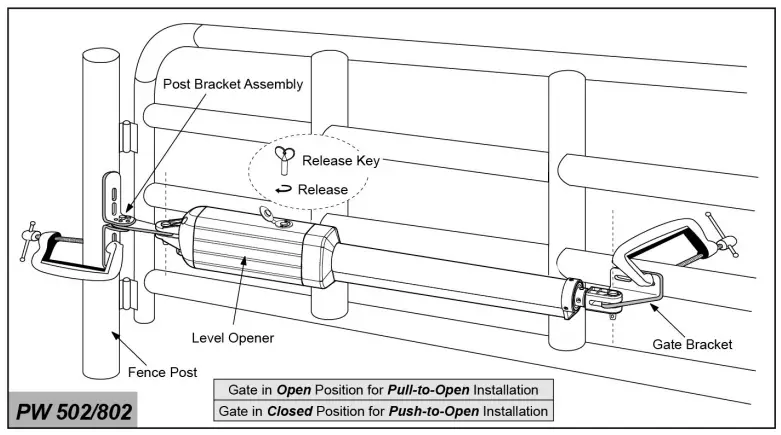

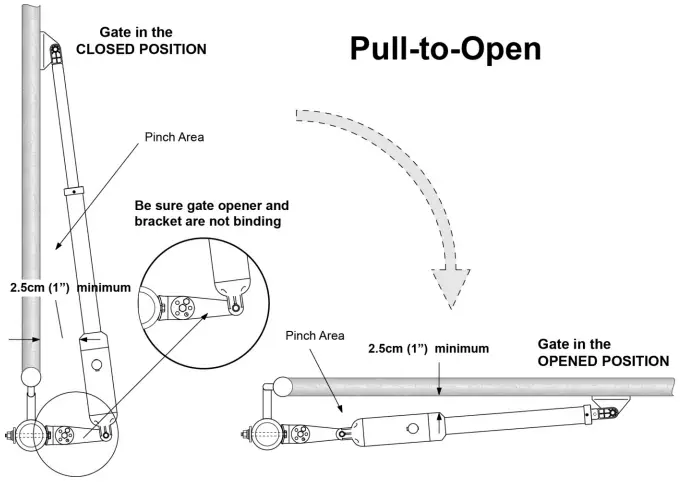

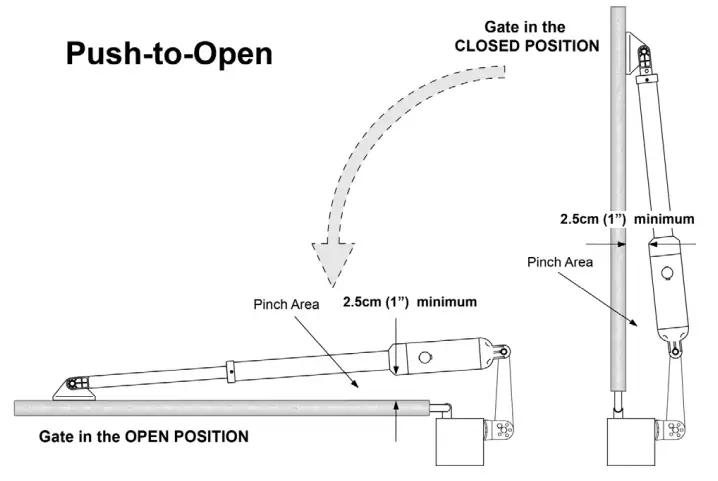

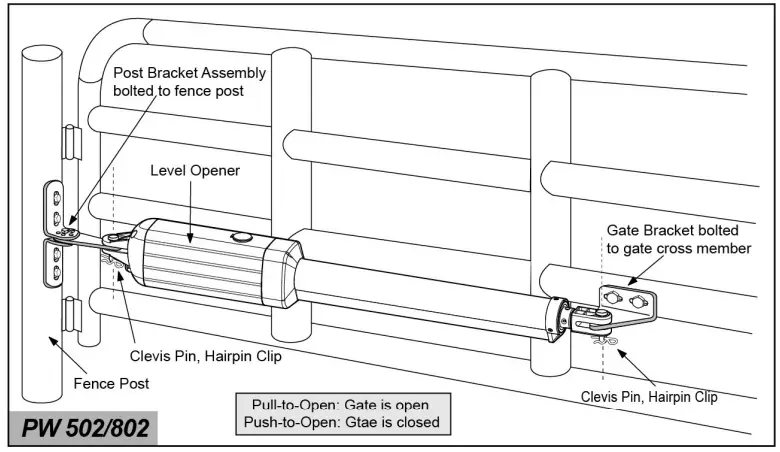

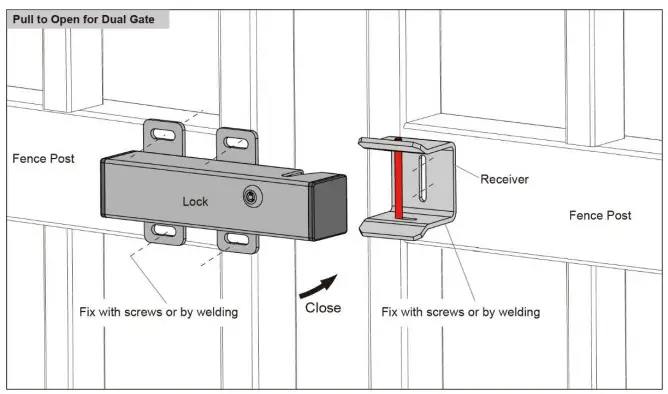

There are two installation types for the gate opener, Pull-to-Open, and Push-to-Open.

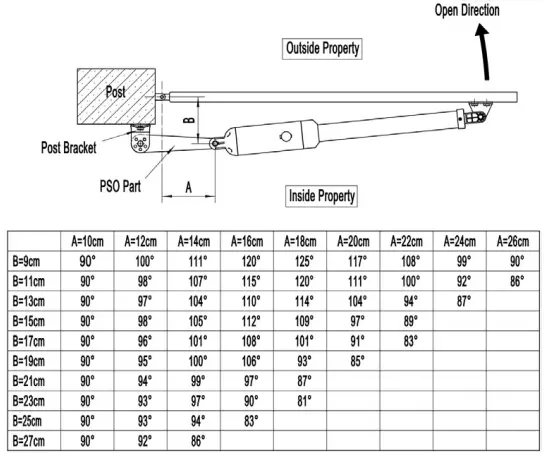

In the Push-to-Open installation, the gate opens out from the property. A Push-To-Open Bracket (PSO part) is

required to be used for each gate.

NOTE: Ensure the gate does not open into public areas.

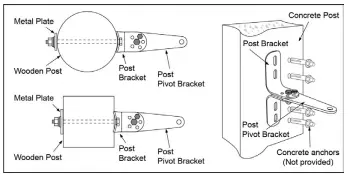

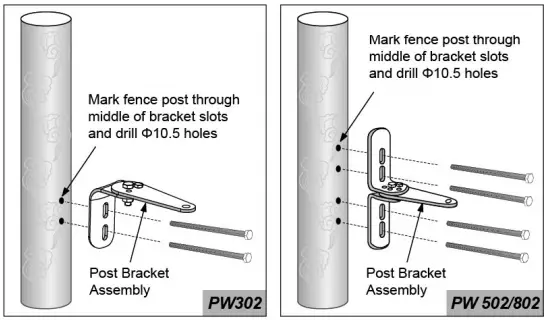

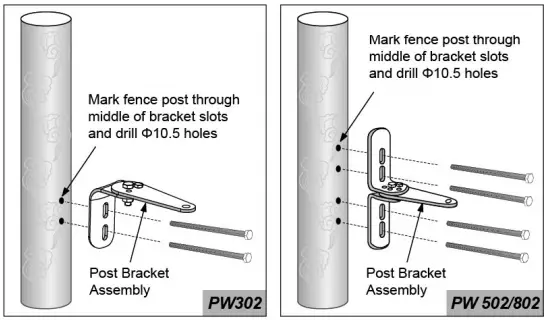

The gate opener is mounted to the gate and to the gate post. Both round and square posts can be used because the Post Brackets are curved. When mounting the Post Brackets, use bolts long enough to pass through the entire post. M10 x 200 bolts are included. Concrete anchors are not provided.

When mounting the Post Brackets to wooden posts, a larger-size washer or metal plate should be used between the bolts and the wooden post to ensure the stability of the fastening hardware. If the post is smaller than 6″ diameter or square, it should be made of metal and set in cement to ensure its stability.

Install the Gate Opener on the Gate

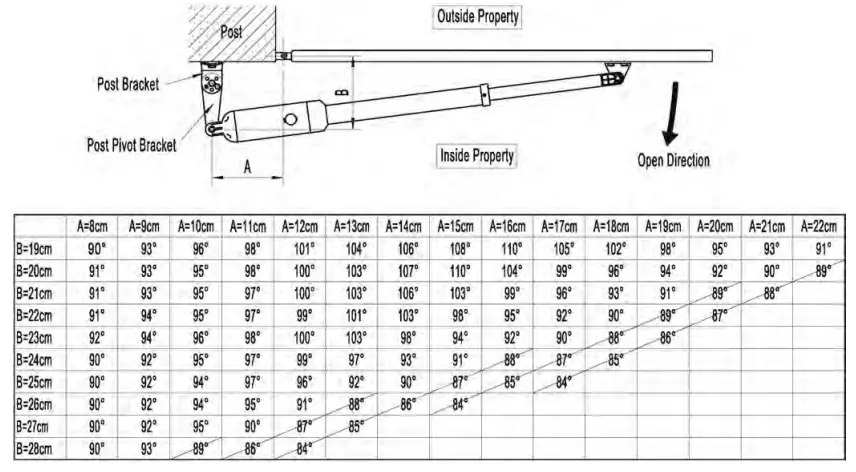

The position of Post Bracket is very important. The following illustrations and tables are required to determine the proper mounting position for the Post Bracket. The tables show the maximum opening angle of the gate for a given A and B. For example, if A is 15cm and B is 20cm, the maximum opening angle of the gate is 110°.

Pull-to-Open Installation — Gate in Closed position (Moving-Rod is extended)

Push-to-Open Installation — Gate in Closed position (Moving-Rod is retracted)

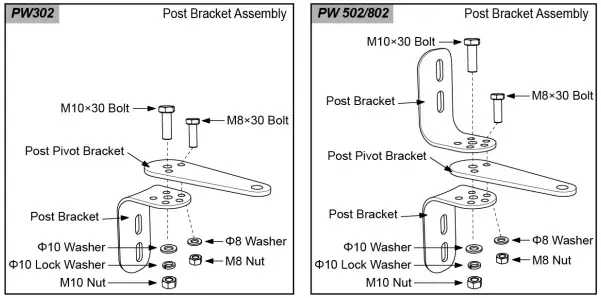

- Insert the M10 x 30 bolt through the center hole of the post bracket and post pivot bracket as shown. Place a ¢10 washer , ¢10 lock washer and M10 nut on the bottom of the bolt and hand tighten.

- Attach the gate bracket and post bracket assembly to the opener by inserting a clevis pin. Secure the clevis pins using the hairpin clips.

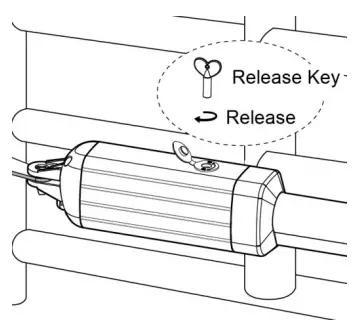

- Open the release hole plug on the top of the gate opener, insert the release key, and turn the key 90° clockwise. This releases the motor and allows the push-pull rod to be manually extended and retracted. To restore normal operation, turn the key 90° counterclockwise.

- With the opener fully retracted and with the gate in the fully open position (for Pull-to-Open installation) or fully closed position (for Push-to-Open installation), place the gate opener with the Post Bracket Assembly and Gate Bracket on the gate post and the gate. Position the Post Bracket Assembly and Gate Bracket so that the gate opener is level.

While holding the gate opener in the level position, temporarily secure it with two C-clamps.

- Make sure that there is a minimum clearance of 2.5cm between the gate and the opener and that the operand the Post Pivot Bracket is not binding in both the gate-open and gate-closed positions. If there is not at least 2.5cm of clearance or if the opener and the Post Pivot Bracket are binding, rotate the Post Pivot Bracket and/or move the Post Bracket Assembly to obtain the minimum clearance and eliminate the binding. When the minimum clearance has been obtained and any binding has been eliminated, place the M8 x 30 bolt through the aligned holes in the Post Bracket and the Post Pivot Bracket.

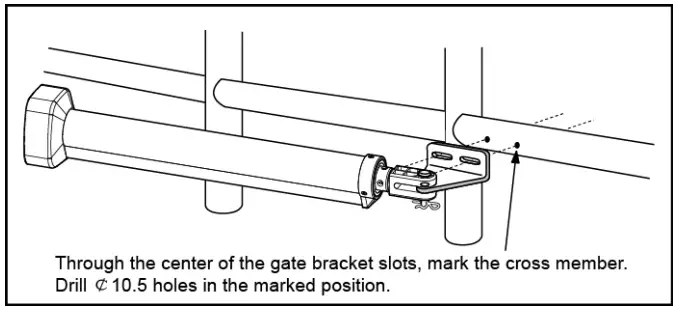

- Sign the bolt-hole point on the gate bracket and gate. Do this by placing a punch or a sign in the middle of each bolt slot on the post bracket assemblies and the gate bracket. It allows slight adjustments to the post bracket. Then remove the post bracket and gate bracket by taking off the C-clamps

- Drill 10.5 mm diameter holes through the post and the gate at the marked locations.

- Attach the post bracket assemblies to the gate posts by inserting M10 x 200 bolts through each post bracket assembly and the drilled holes in the gate post. Fasten each bolt with one ¢10 washer, one ¢10 lock washer, and one ¢10 nut.

- Attach the gate brackets to each gate by inserting two M10 x 75 bolts through the gate brackets and the

drilled holes in the gates. Fasten each bolt with one ¢10 lock washer and one ¢10 nut.

- Cut off any part of the bolts that extend beyond the tightened nuts.

- With the gate opener fully retracted and with the gate in the fully open position (for Pull-to-Open installation) or fully closed position (for Push-to-Open installation), attach the gate opener to the Post Bracket Assembly and the Gate Bracket by inserting a clevis pin through the gate opener and the Post Pivot Bracket and another clevis pin through the gate opener and the Gate Bracket. Secure each clevis pin with a hairpin clip.

- Open the release hole plug on the top of the gate opener, insert the release key, and turn the key 90°

counterclockwise. This restores normal operation.

NOTE: The setting of the PULL/PUSH TO OPEN of the control board should be in accordance with the installation.

Mounting of the Control Box

Use 4 deck screws (not provided) to install the control box. Even though the control box is waterproof designed, for safety reason and a longer service life, it is recommended to install the control box inside a

secure surface and at least 100 cm (40 inches) above the ground to avoid being flooded or buried under snow.

Connection of the Power Supply

The gate opener could be powered by either the 24VDC

The gate opener could be powered by either the 24VDC

AC-DC power supply which is included in the package or 2 PCS 12VDC batteries (connected in series, at least 12AH, NOT INCLUDED) which can be charged by a solar panel. We recommend you to use the AC-DC power supply as the power source to save the cost if the AC electricity is accessible.

Once if you choose the batteries as the power source, it’s no need to use the AC/DC power supply

Once if you choose the batteries as the power source, it’s no need to use the AC/DC power supply

which is included in the package. You must purchase spare solar panel (at least 20W) and solar controller (24V, 10A with over-charge and over-discharge protection) to charge the batteries. Marine or Automotive Type Battery with a capacity greater than 12 AH is required (NOT INCLUDED). 2 PCS 12VDC

batteries can be connected in series to become 24VDC to power up the gate opener. The following diagram will show you how to connect 2 PCS batteries in series. Please note the wire connection of them is very important. Incorrect wire connection will damage the control board. The batteries should be a waterproof type or you should place them in a waterproof housing.

WARNING: NEVER connect the gate opener to the power outlet before all the installations have been done.

WARNING: NEVER connect the gate opener to the power outlet before all the installations have been done.

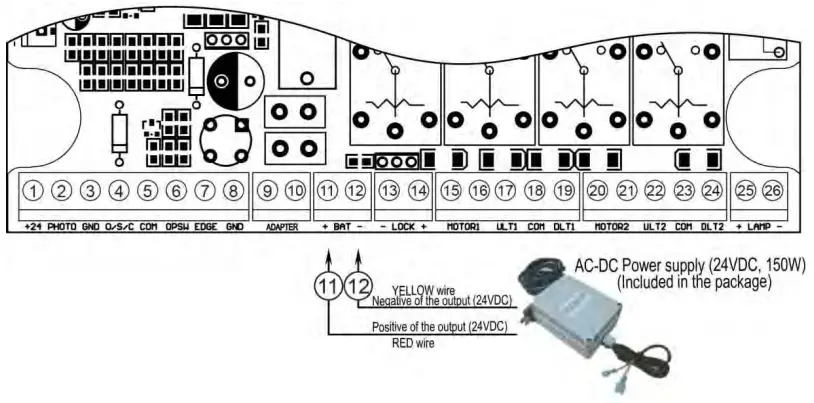

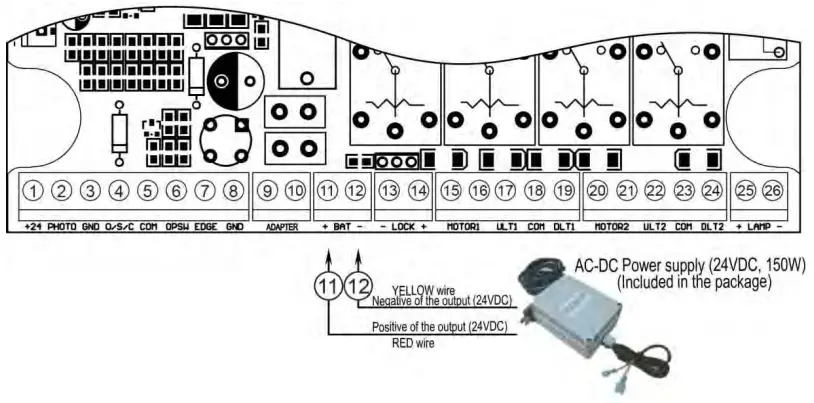

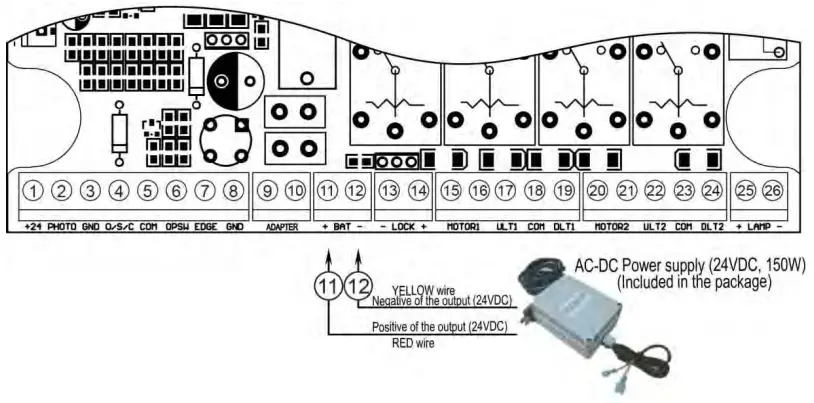

1. Use the DPS180-U power supply as the power source

The positive output (RED wire) of the 24VDC power supply should be wired to the BAT+ (#11) terminal, and the negative output (YELLOW wire) should be wired to “BAT-” (#12) terminal. 2. Use the batteries (Not included) as the power source and use the solar panel to charge the batteries

2. Use the batteries (Not included) as the power source and use the solar panel to charge the batteries

You can choose the batteries to power up the gate opener if the AC electricity is not accessible. Please note you

must purchase a spare solar panel (at least 20W) and solar controller (24V, 10A with over-charge and over-discharge protection) to charge the batteries. The gate opener can work for 10 cycles per day if there is no other accessory except photocell & electric lock & push button& Warning Light connected to the control board if you use the 20W solar panel. The capacity of the batteries and the power of the solar panel should be enlarged if you want to use more times a day. You can connect the solar panel and the solar charge controller refers to the following illustration (e.g.: using TOPENS TSP solar panel & TCS3 solar controller). Connection of the Control Board

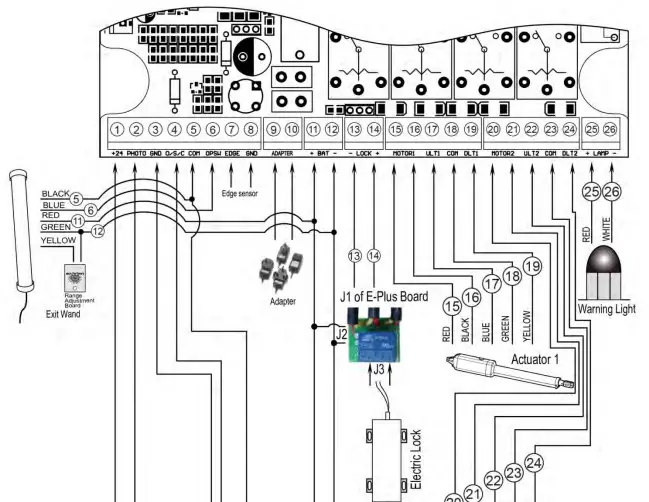

Connection of the Control Board

Almportant Note: This gate opener can be powered by either the 24VDC supply which is included in the package or 2 PCS 12VDC batteries (connected in series, at least 12AH. NOT INCLUDED) which can be charged by solar panel. Please connect the batteries& solar panel & solar controller refers to the chapter -Connection of Power Supply”

Almportant Note: This gate opener can be powered by either the 24VDC supply which is included in the package or 2 PCS 12VDC batteries (connected in series, at least 12AH. NOT INCLUDED) which can be charged by solar panel. Please connect the batteries& solar panel & solar controller refers to the chapter -Connection of Power Supply”

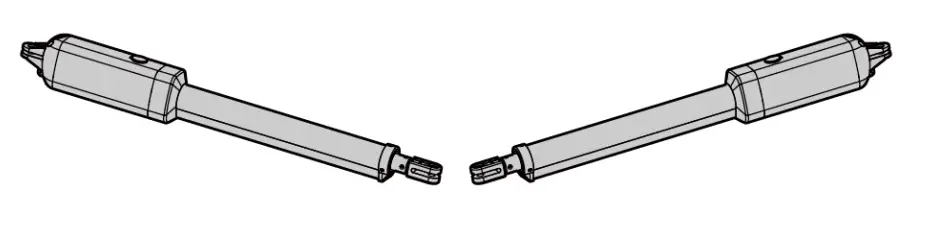

- Actuator 1 (Master gate, open first & close last)

Insert the stripped cable wires into the appropriate terminals on the opener terminals block. The red wire should be inserted into the “+MOTOR1” terminal(#15), the black wire into “MOTOR1-” terminal (#16), the blue wire into “ULMT1” terminal(#17), the green wire into “COM” terminal(#18), and the yellow wire into “DLMT1” terminal (#19). - Actuator 2 (Slave gate, close first & open last)

The red wire should be inserted into the “+MOTOR2” terminal(#20), the black wire into “MOTOR2-” terminal(#21), the blue wire into “ULMT2” terminal(#22), the green wire into “COM” terminal(#23), and the yellow wire into “DLMT2” terminal (#24). - AC-DC power supply

Please connect them refers to the chapter “Connection of the Power Supply”. - Battery & Solar panel & Solar controller (Optional, Not included)

Please connect them refers to the chapter “Connection of the power supply”. - Warning Light (Included in some models, refers to the actual package)

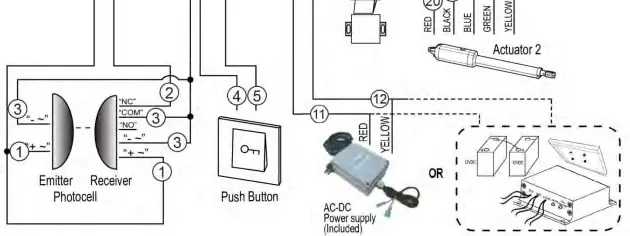

The red wire of the warning light should be inserted into either LAMP (#25) terminal, the white wire into the other one (#26). - Photocell Beam System (PBS) (Included in some models, refers to the actual package)

Use a 2-core cable to connect the “+ ~” terminal of the photocell’s emitter to the “+24” (#1) terminal, the “- ~” terminal to the “GND” (#3) terminal. Also the “+ ~” and “- ~” terminals of the photocell’s receiver should be connected to the “+24” and “GND” terminals in parallel.

Use another 2-core cable to connect the “NC” terminal of the receiver to the “PHOTO” (#2) terminal, the “COM” terminal to the “GND” (#3) terminal. - Push Button (optional)

The push-button should be wired to the “#4 and “#5” terminals. No matter the polarity. The gate operator works alternately by pressing the button (open-stop-close-stop-open). - Electric Lock (optional)

A lock plus board is required to connect the electric lock to the control board. The 2 wires of J1 of lock plus should be wired to the “13#” and “14#” terminals of the control board. No matter the polarity. The red wire of J2 should be wired to the 11# terminal and yellow wire of J2 should be wired to the 12# terminal. Red wire of J3 should be connected to the red wire of electric lock and also the yellow wire of J3 should be connected to the yellow wire of electric lock.

NOTE: If you use the 24VDC AC-DC power supply as the power source and intend to use the electric

lock, the open delay time of the 2 actuators should be more than 4S. - Exit Wand (optional)

The BLACK wire of the exit wand should be connected into the “#5” terminal.

The BLUE wire of the exit wand should be connected into the “#6” terminal.

The RED wire of the exit wand should be connected into the “#11” terminal.

The GREEN wire of the exit wand should be connected into the “#12” terminal.

The sensitivity adjustment board should be wired to the GREEN wire and the YELLOW wire of the wand. No matter the polarity.

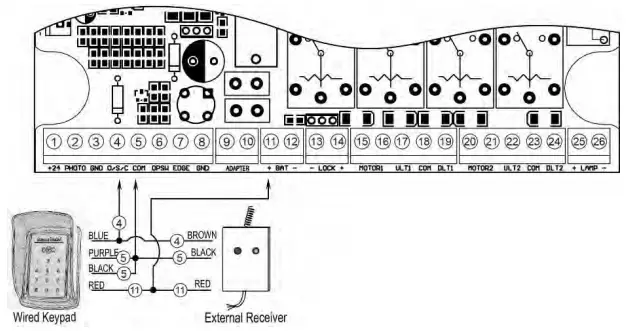

- Wired Keypad (24VDC)(optional)

The RED wire of the wired keypad should be connected into the “#11” terminal.

The BLACK wire of the wired keypad should be connected into the “#5” terminal.

The PURPLE wire of the wired keypad should be connected into the “#5” terminal.

The BLUE wire of the wired keypad should be connected into the “#4” terminal. - External receiver (optional)

The RED wire of the external receiver should be connected into the “#11” terminal.

The BLACK wire of the external receiver should be connected into the “#5” terminal.

The BROWN wire of the external receiver should be connected into the “#4” terminal.

Note: Using of the exit wand, keypad and external receiver would cause the battery to exhaust quickly. Big capacity of the battery and big power of solar panel (if the battery is used as power source) is required if you want to use either of them.

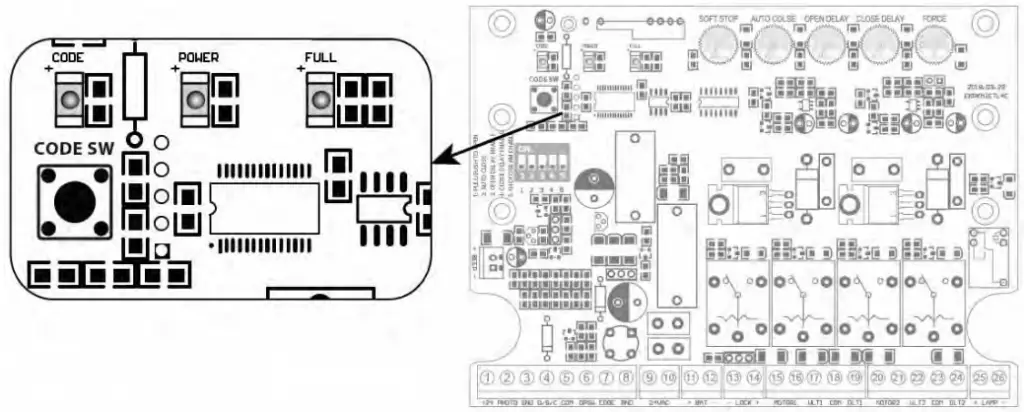

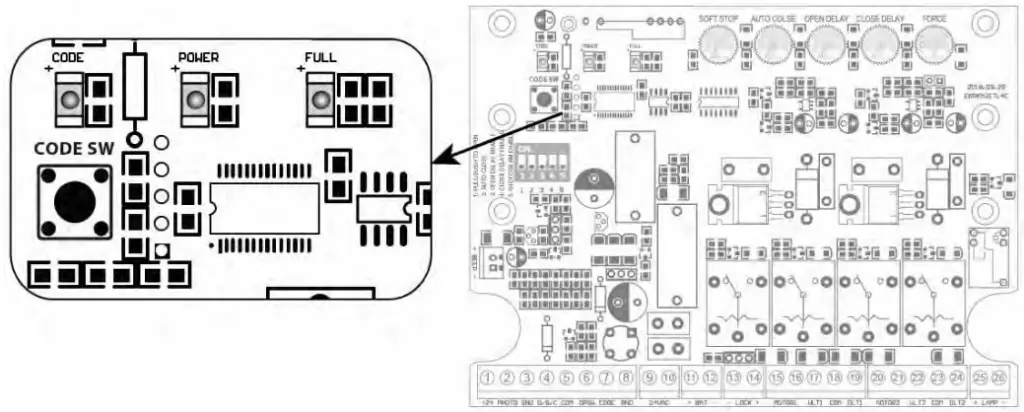

How to Program the Remote to the Opener

- The remote MUST be programed to the opener BEFORE OPERATING. Please follow the steps to program the remote.

- Activate the opener only when gate is in full view, free of obstruction, and properly adjusted. No one should enter or leave gate area while gate is in motion. DO NOT ALLOW CHILDREN to operate push button or remote. DO NOT ALLOW CHILDREN TO PLAY NEAR THE GATE.

- If you purchase additional remote controls, the gate opener must be programmed to accept the new remote code.

- If you lose one of any remote control, please erase and reprogram all other remote controls to have a new code for safety.

Press and release the CODE SW button, the CODE LED will be ON, then press the key in the remote twice in 4 seconds, the CODE LED will flash for 3 seconds and then to OFF. Now the remote has been programmed successfully.

NOTE: Max. 8 remotes can be programmed for the opener. An External Receiver (optional) allows up to 250pcs remotes to be programmed for the opener. TOPENS ERM12 Universal External Receiver is available at TOPENS Store.

TOPENS ERM12 Universal External Receiver is also compatible with other brand swing gate opener, sliding gate opener and garage door opener.

How to Erase All the Remote Codes

Press and hold the CODE SW button until the CODE LED from ON to OFF. Now all remote codes have been erased.

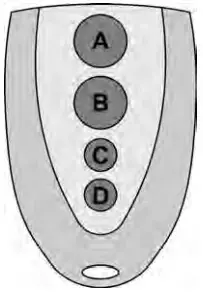

How to Use the Remote to Operate Your Gate Opener

Each remote has four buttons, from top to bottom are separately A, B, C and D. You may use this remote to operate as many as 4 sets TOPENS swing gate openers or 1 set TOPENS sliding gate opener and 2 sets TOPENS swing gate openers.

- Use this remote to only operate TOPENS swing gate opener A, B, C and D four buttons share same function once they are programmed with TOPENS swing gate opener. You may choose any button to program it with our swing gate opener. Every press of the button is able to active the gate opener to work alternately (open-stop-close-stop-open)

- Use one remote to operate TOPENS swing gate opener & sliding gate opener at the same time All of TOPENS sliding gate opener have midway mode. Button B is designed to realize midway function (refer to more details in our TOPENS sliding gate opener manual). So it is must program button A with sliding gate opener, while you may program either C button or D button with TOPENS swing gate opener.

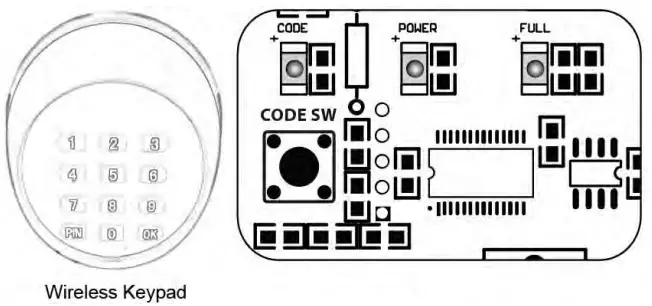

Wireless Keypad Programming

You can follow the below steps to program wireless keypad to the opener. Press the CODE SW button until the CODE LED is ON, and then release the button. Then press “OK” button on keypad and CODE LED will flash for3 seconds and then be OFF which indicates the keypad has been programmed successfully. You can use the default password “888888” to operate the opener after programming. You can press “PIN” “8 8 8 8 8 8” and then press “OK” to confirm to operate the opener.

Also, you can change the password of the keypad follow the below steps. Press “PIN” and then input the six digits old password and then press ”PIN” again, the CODE LED will be ON. Input the six digits new password and then press the “PIN” to confirm the new setting, CODE LED will flash for 3 seconds and then be OFF which indicates the password has been changed successfully. You can press “PIN” “6 digits new password” and then press “OK” to confirm to operate the opener.

NOTE: Every step for pressing button during program must be finished within 1 second to ensure successful programming.

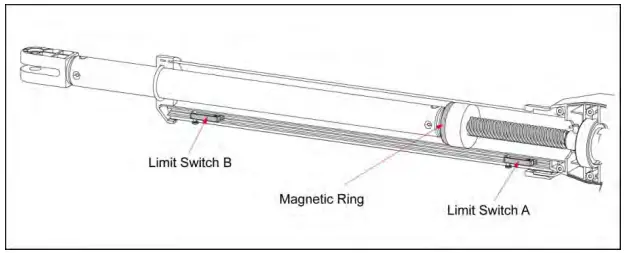

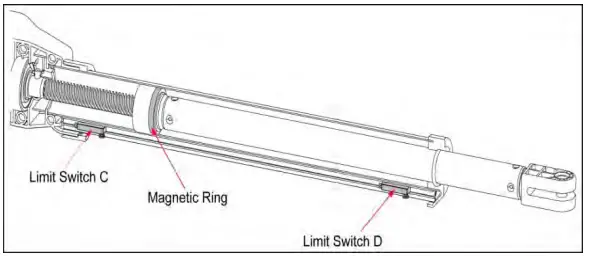

Adjusting the Limit Switch

Adjusting the Limit Switch of Actuator 1

The position of Limit Switch A was fixed in factory, do not adjust it again.Plug on the power to running gate

opener, use a screwdriver to loose the screw of Limit Switch B, slide Limit Switch B to the desired closed position and fix it. Limit setting for Gate 1 is finished now.

NOTE: Always place the magnetic ring between the Limit Switch A and B.

Adjusting the Limit Switch of Actuator 2

Adjusting the Limit Switch of Actuator 2

The position of Limit Switch C was fixed in factory, do not adjust it again. Use a screwdriver to loose the screw of Limit Switch D, slide Limit Switch D to the desired closed position and fix it. Limit setting for Gate 2 is finished.

NOTE: Always place the magnetic ring between the Limit Switch C and D.

NOTE: The magnetic ring in the moving rod can be manually placed between both Limit Switches in each

actuator by releasing the clutch.

Setting of the Control Board

WARNING: Ensure the gate opener is Power Off when you make any adjustment of the gate opener. Keep away from the gate during you set the gate opener system in case of the unexpected gate moving. Carefully adjust the DIP switches to avoid the risk of machine damage and injury or death. Always ask the help of a professional technician /electrician if you have any questions.

WARNING: Ensure the gate opener is Power Off when you make any adjustment of the gate opener. Keep away from the gate during you set the gate opener system in case of the unexpected gate moving. Carefully adjust the DIP switches to avoid the risk of machine damage and injury or death. Always ask the help of a professional technician /electrician if you have any questions.

1. DIP Switches

The DIP switches are used to select pull/push to open, enable/disable auto-close function, enable/disable open the interval between the master and slave gate opener, enable/disable close interval between the master and slave gate opener and enable/disable photo beam function.

DIP Switch #1: Select push/pull to open

If the gate opens into the property (pull to open), the DIP Switch is set to OFF (factory default setting). If you gate opens out from the property (push to open) the DIP Switch must be set to the ON position.

Factory default setting is OFF.

DIP Switch #2: Auto close function enabled/disabled

ON – Auto close function enabled

OFF – Auto close function disabled

Set the switch #2 to ON to enable the auto close function. Factory default setting is OFF.

DIP Switch #3: Enable/disable open interval between the master and slave gate opener

ON – Open interval is enabled

OFF –Open interval is disabled

Factory default setting is ON.

NOTE: Open interval time can be adjusted by the OPEN DELAY potentiometer.

DIP Switch #4: Enable/disable close interval between the master and slave gate opener

ON – Close interval is enabled

OFF –Close interval is disabled

Factory default setting is ON.

NOTE: Close interval time can be adjusted by the CLOSE DELAY potentiometer.

DIP Switch #5: Photocell function enabled/disabled

ON – Photocell function enabled

OFF – Photocell function disabled

You must set the switch #5 to ON to enable the photocell function if you want to use the photocell with the gate opener. Factory default setting is OFF.

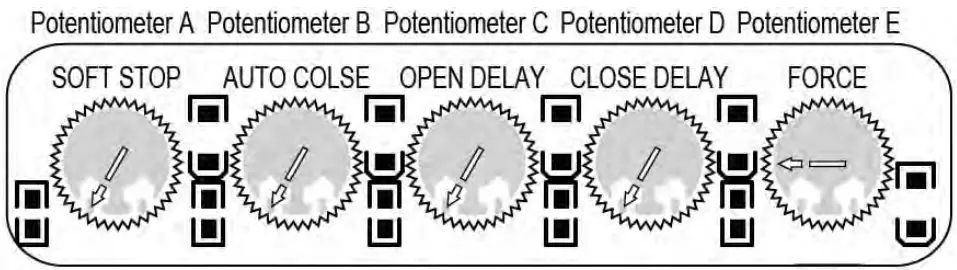

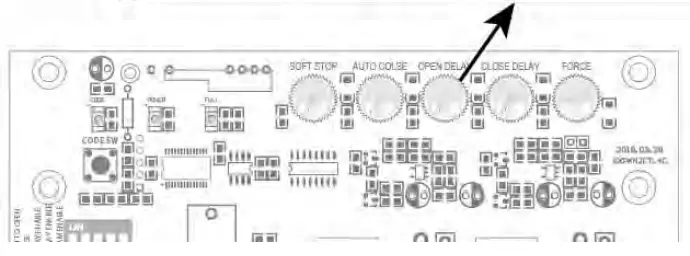

2. Potentiometers

There are 5 potentiometers located in the control board. They are used to adjust soft stop period, auto-close time, open interval and close interval time between master gate opener and slave gate opener, and the stall force.

Potentiometer A is used to adjust the soft stop period of the gate opener. Turn the potentiometer clockwise to increase the soft stop period, and turn it counter-clockwise to decrease the soft stop period. The soft stop period can be adjusted steplessly from 1 to 5 seconds.

Potentiometer B is used to adjust the auto-close time of the gate opener. Turn the potentiometer clockwise to increase the auto-close time, and turn it counter-clockwise to decrease the auto-close time. The auto-close time can be adjusted steplessly from 3 to 120 seconds.

Potentiometer C and potentiometer D are used to adjust the open interval and close interval time between the master gate opener and the slave gate opener respectively. Turn the potentiometer clockwise to increase the interval time, and turn it counter-clockwise to decrease the interval time. The interval time can be adjusted steplessly from 1 to 9 seconds.

Potentiometer E is used to adjust the stall force the gate opener. Turn the potentiometer clockwise to increase the stall force, and turn it counter-clockwise to decrease the stall force.

Maintenance

Warning: Disconnect power before servicing.

Warning: Disconnect power before servicing.

- Using a clean, dry cloth to wipe the gate opener shaft, and then apply a silicone spray to reduce its friction. In cold climates where temperatures reach 1°C (30°F) or less, spray silicone on the actuator every 4~6 weeks to prevent freeze up.

- Regularly check gate hinges to make sure gate is swinging smoothly and freely. Grease hinges if needed.

- Check your installation periodically, as hardware and posts will shift. Brackets may need to be adjusted or hardware may need to be tightened.

- Maintain the area around your gate. Keep the areas free of objects that can prevent the gate from swinging freel

NOTES:

- Inspection and service should always be performed anytime a malfunction is observed or suspected.

- It is suggested that while at the site voltage readings be taken at the operator. Using a Digital Voltmeter, verify that the incoming voltage to the opener it is within ten percent of the opener’s rating.

- Refer to the instructions on how to check gate force and sensitivity adjustments.

Status of gate opener Status of LED(s) Possible Solution(s) Standby CODE LED POWER LED FULL LED Running OFF Flash(1 Blink every second) OFF Normal (Voltage of thebattery is normal) Standby Flash(1 Blink every second ) Flash(1 Blink every second) Flash(1Blinkevery second) Normal Both of the gates do not move when operating OFF Flash(1 Blink every second) Normal ON Normal (Battery is full) Both of the gates do not move when operating OFF Flash quickly for 3 seconds and then back to OFF OFF 1. Make sure the remote has been programmed to the control board before using.

2. The battery of the remote may be exhausted. Replace the battery and try it again.

3. The control board could be faulty. Replace the control board as necessary.Standby OFF Flash(1 Blink every 2 seconds) OFF 1. Check the power supply of the gate opener is connected or not. The batteries or a 24Vdc AC/DC power supply must be used to power the gate opener.

2. Check the fuse.

3. Check if the wire connection of the power supply is loosening or notThe gate reverse when on the way of opening or closing Flash(1 Blink every second ) Flash quickly until the gate stop running OFF Voltage of the battery is low, wait the battery to be charged. Both of the gates donot move when operating OFF Flash quickly for 3 seconds and then back to flash slowly(1 Blink every 2 seconds) Flash(1 Blinkevery second) 1. Ensure that the gates swing freely without any binding.

2. The stall force is adjusted too small. Turn the Potentiometer E to increase the force. 3. Ensure the photo beamis not blocked when a photocell is used.Both of the gates do not move when operating Flash quickly for 3seconds and thenback to OFF Flash quickly for 3 seconds and then back to flash slowly(1 Blink every second) OFF Voltage of the battery is low, wait the battery to be

charged.

Both of the gates do not move whenoperating OFF Flash quickly for 3 seconds and then back to flash slowly(1 Blink every second) Flash quickly for 3 seconds and then back to OFF 1. Ensure the photo beam is not blocked when a photocell is used. 2. Check if the photocell is defective or not. The gate stop when on the way of opening or closing Flash quickly for 10seconds and then back to OFF Flash quickly for 10 seconds and then back to flash slowly(1 Blink every second) OFF Check if the jumper wire between the EDGE and GND terminal is loosening or not. The gate stop when on the way of opening or closing OFF Flash quickly for 10 seconds and then back to flash slowly(1 Blink every second) Flash quickly for 10 seconds and then back to OFF Two sequential photo beam blocked has been detected. Please ensure the photo beam is not blocked. Both of the gates do not move when operating Flash quickly Flash quickly Flash quickly 1. Two sequential contact entrapments have been detected. Please ensure there is no obstacle on the path of opening or closing.2

. Adjust the stall force bigger.One gate runs normally but the other one does not move Flash(1 Blink every second ) Flash(1 Blink every second) Flash(1 Blink every second) 1. Re-power on the gate opener.

2. Replace the control board as necessary.1. Exchange the wire connection of the 2 arms and check what will happen to the 2 arms. If the faulty arm is still faulty, then the arm itself is faulty. If the failure changes to the other arm which worked normally before, then the control board is faulty.

2. If the arm is confirmed faulty by step 1, you can connect the RED & BLACK wire of the arm to the 24Vdc battery to check if the arm could run normally. If so, then the limit switch of the arm is faulty. If the arm still can’t run, then the motor part which is inside the arm is faulty.Gate automatically opens, but does not automatically close Flash(1 Blink every second ) Flash(1 Blink everysecond) Flash(1 Blink every second) Setting of DIP switch #1 could be wrong. Please set the dip switch correctly according to the push/pull to opener installation of the gate opener.  According to Waste of Electrical and Electronic Equipment (WEEE) directive. WEEE should be eparately collected and treated. If at any time in future you need to dispose of this product please do NOT dispose of this product with household waste. Please send this product to WEEE collecting points where available.

According to Waste of Electrical and Electronic Equipment (WEEE) directive. WEEE should be eparately collected and treated. If at any time in future you need to dispose of this product please do NOT dispose of this product with household waste. Please send this product to WEEE collecting points where available.

TOPENS Website

TOPENS Website

http://www.topenstool.com/

Any question, please do not hesitate to contact us:

E-mail: [email protected]

Kindly include your Product Model, Purchasing Date & Site, Order #, and your contact information. All your concerns will be replied within 24 hours.

Tel: +86 (571) 8908 0213 (China)

Mon-Fri 9:00AM-5:30PM (UTC +08:00)

Important Note:

- The open & close delay time of the 2 actuatorsMUSTbesetto more than 4 seconds, if the electric lock isusedwithdual swing gate opener which is poweredbytheUPS01orDPS180-U AC-DC power supply. Otherwise, thegateopener will work improperly.

- Electric lock improves the safety for your gate, anditishighly recommended if you have animalsor liveinareasaffected by strong winds when the gate islongerthan1.2meters (4 feet).

Electric Lock Part List

Important Information:

1

- Before you install the Electric Lock please be sure the gateis level ,moves freely, and does not bind or block against barriers. 2

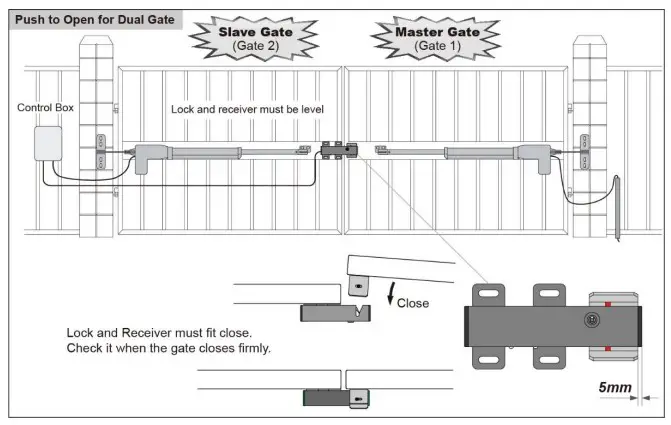

- On the Pull-to-Open installation, for the Electric Locktoworkproperly, in order to ensure the lock engaging with the lockr eceiverf irmly, the limit switch B must be moved outward a littlebit morethanthe desired close position. 3. Due to the various mounting conditions, mounting hardwareisnotprovided. Read this manual carefully to determine the mountinghardware required for your condition.For dual gate, the lock must be installed on the Master Gate (gate 1) which is near the Control Box, and the lock receiver must be installed on the Slave Gate (gate 2).

- ( If the gate near the control box has been set up as slave gate, you can change the settings following “User’s Manual” → “Control Board Settings” – “Master/Slave Gate Set” )

Installation for Single Gate

Step 1: Disengage the clutch of the opener with the Release Key. You can move the gate by hand, so the gate can swing freely during installation of the Electric Lock.

Step 2: With the gate in the closed position, determine the best location for the lock and receiver. The lock and receiver must be level and aligned with the opener. The lock and receiver should have a solid surface or tube fence to provide stability. Step 3: For Metallic Tube gate, if the thickness of the fence post is bigger than or equal to 3mm, you can thread on the fence post, and fasten the lock and receiver only using bolts (without nuts). Otherwise, drill holes through out the fence post, and fasten the lock and receiver with bolts, lock washers and nuts. Of course, you can weld them directly.

For Chain Link gate, you will need U-Bolts, saddles, lock washers and nuts for the lock and receiver.

Step 4: Recheck the lock’s position and alignment, make sure the electric

lock work correctly.

Step 5: Connect the lock’s power cables to the control board of TOPENS swing gate opener refers to the chapter “Wire Connection of the LOCK” . Note: Be sure that the clutch of the opener is engaged before you prepare to activate your opener (Use the Release Key).

Installation for Dual Gate

Step 1: Disengage the clutches of the openers with the Release Key. You can move the gates by hand, so the gates can swing freely during installation of the Electric Lock.

Step 2: With the gates in the closed position, determine the best location for the lock and receiver. The lock and receiver must be level and aligned with the openers. The lock and receiver should have a solid surface or tube fence to provide stability.

Step 3: For Metallic Tube gates, if the thickness of the fence post is bigger than or equal to 3mm, you can thread on the fence post, and fasten the lock and receiver only using bolts (without nuts). Otherwise, drill holes through out the fence post, and fasten the lock and receiver with bolts, lock washers and nuts. Of course, you can weld them directly.

For Chain Link gates, you will need U-Bolts, saddles, lock washers and nuts for the lock and receiver.

Step 4: Recheck the lock’s position and alignment, make sure the electric lock work correctly.

Step 5: Connect the lock’s power cables to the control board of TOPENS swing gate opener refers to the chapter “Wire Connection of the LOCK”. Note: Be sure that the clutches of the openers are engaged before you prepare to activate your openers (Use the Release Key).

Wire Connection of the Lock

The electric lock can be wired to the “LOCK” terminal of the gate opener control board directly, no matter the polarity of the wires.

Wiring Diagram of the E-Lock to the A Series Single Swing Gate Opener

Wiring Diagram of the E-Lock to the AD&PW Series Dual Swing Gate Opener

Wiring Diagram of the E-Lock to the KD902, AT1202, MT8012, MT9012 Swing Gate Opener

NOTE: If the gate opener which you want to use the lock with is not listed in the above diagram, you can find the wiring diagram in the user manual of the gate opener, or contact us for technical support.

www.topens.com Any question, please do not hesitate to contact us:

E-mail: [email protected]

Kindly include your Product Model, Purchasing Date & Site, Order #, and your contact information. All your concerns will be replied within 24 hours.

Tel: +1 (888) 750 9899 (Toll Free USA & Canada)