PENTAIR 320 Rainbow Chlorine Bromine Feeder

Information

It is important to read all information BEFORE proceeding with the installation. The information will guide you in installing your feeder properly and to avoid problems due to improper installation.

IF YOUR POOL OR SPA HAS COPPER PLUMBING . . . STOP!!

Never install the feeder into copper plumbing as pipe damage will occur. (See Equipment Safety CAUTION sheet enclosed). NOTE: If heaters are used, a Fireman’s Switch or equivalent must be installed to prevent possible damage and improper operation of Check Valve and other equipment subject to heat damage.

INSTALLATION INSTRUCTIONS MODEL #320

Note: Make sure all pumps and timer switches are in the OFF position.

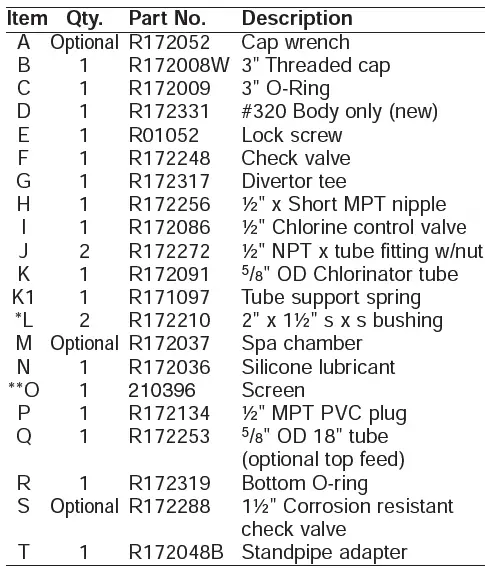

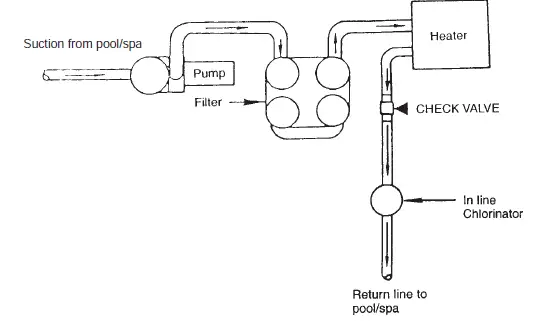

WHERE TO INSTALL YOUR FEEDER

The #320 feeder is designed for permanent installation in the return line of your new pool or spa and must always be installed after the heater, pool cleaner, valves, etc. If your pool does not have a heater, then it must be installed after the filter or any other piece of equipment. DAMAGE TO THE HEATER AND OTHER EQUIPMENT COULD RESULT IF HIGHLY CHLORINATED

WATER FLOWS THROUGH IT.

If your pool is equipped with a solar system it may be necessary to install a HI FLOW KIT. This kit can be installed if your feeder is not getting adequate flow and/or pressure through the system. Refer to the information on sheet enclosed. Your feeder may be installed in existing PVC plumbing but will require a union and/or other fittings. The feeder comes complete for installation with 2″ or 1½” PVC plumbing. Choose a site in the return line where feeder can be installed in a vertical position. Always install as far from any metal equipment as practical since fumes, etc. can corrode them. If optional corrosion-resistant check valve is required refer to installation instructions before next step.

BASIC PLUMBING INSTALLATION INSTRUCTIONS

2″ OR 1½” PVC PIPE: If feeder is being installed on a pool, spa or pool/spa combination, correct plumbing procedures must be followed to insure proper flow through feeder. If pool or spa is plumbed with 2″ PVC pipe, be certain the pump, filter and heater all have 2″ inlet and outlet fittings. If any part of the equipment has less than 2″ fittings or pipe, then a minimum of 6″ x 1½” reducer bushings must be installed directly into the inlet side of the feeder using the 2″ x 1½” reducer bushings supplied. This will build pressure directly into the feeder insuring proper operation. Continue with 2″ PVC pipe on the outlet side of the feeder.

POOL/SPA COMBINATION:

If plumbing and equipment is a full 2″ and the feeder is being installed on the pool return line after the diverter valve, with a portion of the water diverted to the spa, install a minimum section of 6″ x 1½” PVC pipe directly into the inlet side of the feeder using the 2″ x 1½” reducer bushing supplied. Continue with 2″ PVC pipe on the outlet side of the feeder. This will compensate for that portion of water being diverted to the spa. 90° ELBOWS: Plumbing a 90° elbow directly into the inlet side of the feeder may cause turbulence inside the elbow. This will prevent water from being scooped into the feeder. A minimum of a 6″ length of PVC pipe should be installed between the 90° elbow and the inlet side of the feeder.

2″ PVC: Simply glue feeder to the return line using PVC SOLVENT CEMENT. Be sure arrows on feeder point in the direction of water flow returning to the pool or spa.

1½” PVC: Remove (2) 2″ x 1½” slip reducer bushings packed inside the feeder and glue into 2″ slip tee on bottom of feeder. Complete installation by gluing into 1½” return line making sure the arrows on feeder point in the direction of water flow returning to the pool or spa. Use only PVC SOLVENT CEMENT. Follow directions on solvent cement label. Allow to dry. Installation in now complete.

OPERATING INSTRUCTIONS

Before start up of feeder, your pool should be properly conditioned and the residual should be 1.0 to 1.5 ppm.The water in a newly-filled pool should be properly conditioned to insure maximum effectiveness of the feeder. Consult your local dealer for water conditioning information for your area.

- Remove cap of feeder and fill with proper size tablets.

For Pools: 1″ or 3″ dia. tablets For Spas: 1″ dia. tablets in optional Spa Chamber. - Make sure the O-ring is clean, lubricated with Lifegard Silicone and is in place, replace cap. Hand tighten only.

- Turn on the pump and timer switches for a minimum of 6 to 8 hours.

- Adjust control valve according to your pool/spa size. Use a test kit to determine the chemical residual. It is recommended that the chemical residual be checked daily for the first 5 days. Remember . . . hot days, higher water temperature or increased pool/spa activity will cause your pool/spa to use more sanitizer. When possible, increase the feed rate a day or two in advance. Because the chlorine demand in your pool/spa varies and is dependent on many factors (sunlight, bather load, water temperature, etc) your valve setting may have to be changed from time to time to adjust to these conditions. For example, the winter setting may be #2 while the summer setting is #3. Check the chlorine residual daily to find the ideal setting. Note: Higher numbers dispense more chemical. Small gradual changes are imperative for control.

HOW TO RECHARGE FEEDER

- Turn control valve to the closed position. SHUT OFF PUMP.

- Wait one minute. This will allow water and fumes to drain from feeder.

- Leave control valve closed and turn on pump. The check valve will prevent water from entering the feeder.

- Remove cap and fill with proper size tablets or sticks. (See Operating Instructions #1)

- Making sure O-ring is clean, lubricated with Lifegard silicone and is in place, replace cap. Hand tighten only.

- Open control valve to original setting. Inspect inlet line below control valve each time feeder is recharged. Replace lines yearly if necessary.

SPECIAL FEATURES AND INSTRUCTIONS

If while using 3″ diameter tablets the #320 feeder does not provide enough chlorine residual, switch to 1″ tablets. The smaller tablet will erode faster producing more chlorine residual. If this does not correct the situation, the #320 has been fitted with an optional opening at the top of the feeder (which is plugged). To accommodate attachment of the valve and tubing assembly for top entry of water into the feeder, an additional length of tubing has been included.The following procedure should only be used if the suggested change has not solved the situation. Top entry in normal situations can cause over-chlorination.

- Turn off pump and timer switches.

- Remove tubing by unscrewing the compression nut at each end of tubing.

- Remove plug at top of the feeder directly above control valve.

- Remove the control valve. If nipple stays in valve, carefully remove by using pliers at the center of nipple. There is no need to remove the 90° tube fittings.

- Wrapping with 2 or 3 wraps of threaded tape in the opposite direction of tightening. Screw into the opening where control valve was attached. Hand tighten plus 2 or 3 turns. Do not overtighten.

- Wrap threads of nipple with threaded tape.Thread nipple into top opening.Finger tighten only. Thread valve onto nipple. After nipple starts to turn from tightening valve, 2 to 3 more turns is enough. The nipple or valve can be broken by overtightening.

- Slide compression nut over long section of tube. Slide tube over tapered part of 90°tube fitting and tighten. Hand tighten only. Repeat for another end of tubing.

- Set control valve to #1. Turn on the pump and timers. Check residual daily to determine proper setting. Small gradual changes are imperative for control.

BELOW WATER LEVEL INSTALLATION

Feeder should be installed above water level whenever practical. If installed below water level, a drain valve must be installed to prevent spillage and dangerous splash back of high chlorinated water during recharging. Drill and tap a ¼” MPT hole at the same level the control valve is located. Make sure there is no water or tablets inside the feeder before drilling. Install optional drain valve, Part R172060, or suitable chemical resistant drain valve.

BELOW WATER LEVEL RECHARGING INSTRUCTIONS

- Shut off pump and timer switches.

- Shut off the control valve.

- Place a clean container under drain and open drain valve.

- Exercise extreme caution when opening or servicing feeder. Do not inhale fumes. Wear protective gear. Remove cap.Water will now drain from feeder. Empty container back into pool or spa.

- Close drain valve. fill with proper size tablets or sticks.

- Make sure the O-ring is clean, lubricated with Lifeguard Silicone and in in place, replace cap.

- Turn on pump and timer switches.

- Reset control valve to the original setting. Inspect inlet and outlet line each time feeder is recharged. Replace lines yearly if necessary.

D A N GER

READ CAREFULLY

This feeder is designed to use only CLEAN Trichlor-s-trizinetrione OR CLEAN Bromine tables – slow dissolving type. Never use dirty tablets. UNDER NO CIRCUMSTANCES MIX Trichlor or Bromine with Calcium Hypochlorite, with other forms of concentrated chlorine or with other chemicals. Keep inside of feeder clean of dirt and debris at all times. FIRE AND/OR EXPLOSION MAY RESULT. NEVER use oils or grease to lubricate o-ring. Oil in contact with Trichlor OR Bromine may result in FIRE. Lubricate o-ring with Lifegard Silicone o-ring Lubricant ONLY, available at your dealers. If shock treatments or Algaecides containing chemicals other than sanitizers tablets in feeder must be used, turn off Feeder OR remove tablets until the shock or Algae treatment is complete and all granules have dissolved. Failure to do so may result in granules mixing in feeder causing FIRE AND/OR EXPLOSION. The shock or algae treatment dissolved in water is safe with tablets. If you are not the original owner of this feeder, not sure which chemicals was used, or if dirt and/or debris inside feeder, be SAFE and flush thoroughly with fresh water. CAUTION SHOULD BE USED

WHEN REMOVING CAP. DO NOT INHALE FUMES.

CALCIUM HYPOCHLORITE IS NOT TO BE USED IN ANY FORM. Use of chemicals other than listed by the manufacturer may be hazardous.

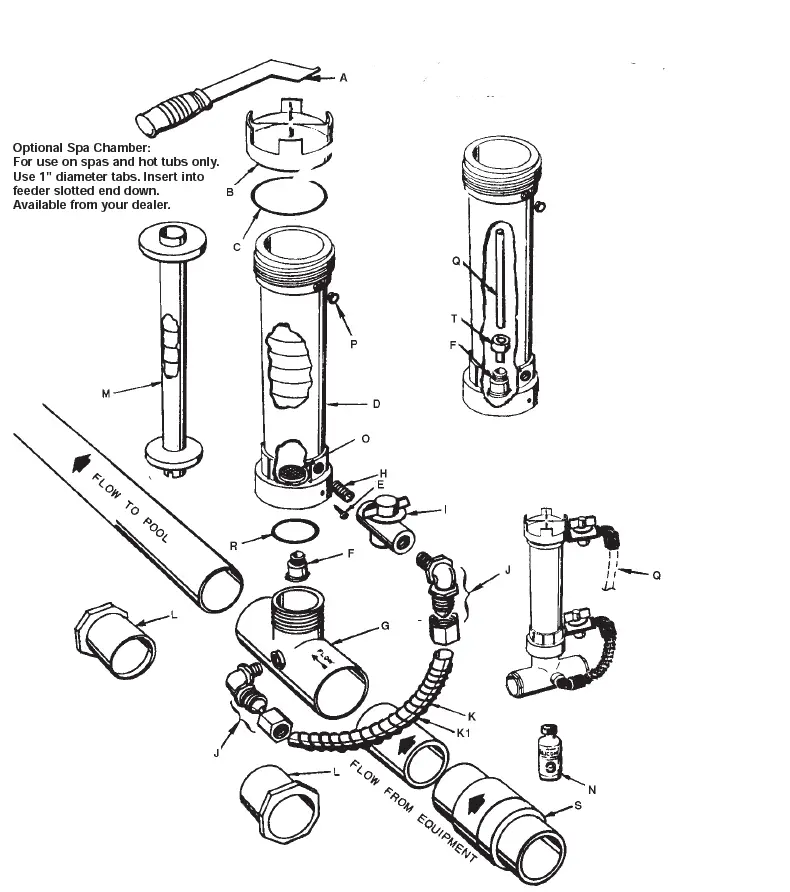

Bromine Standpipe Installation

To increase erosion of small bromine tablets, install Bromine Standpipe as follows:

- Remove screen from bottom of chamber exposing check valve (F)

- Insert adapter (T) into check valve opening.

- Cut supplied 5/8″ black tube (Q) to 6″ length and push tube into adapter opening.

YOU MAY SUBSTITUTE BROMINE TABLETS OR STICKS FOR TRICHLOR IN THIS FEEDER. DO NOT MIX.

CALCIUM HYPOCHLORITE IS NOT TO BE USED IN ANY FORM.

IMPORTANT OPTION.

SEE CORROSION CAUTION SHEET.

CAUTION

Do not install feeder into copper plumbing. Pipe damage could occur. Never install feeder before heater. Heater damage could occur.

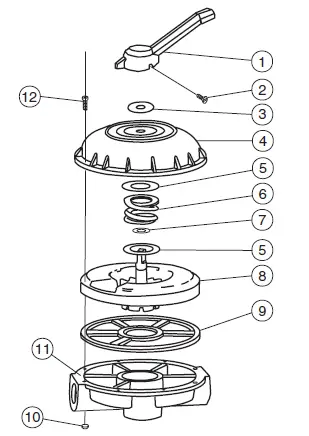

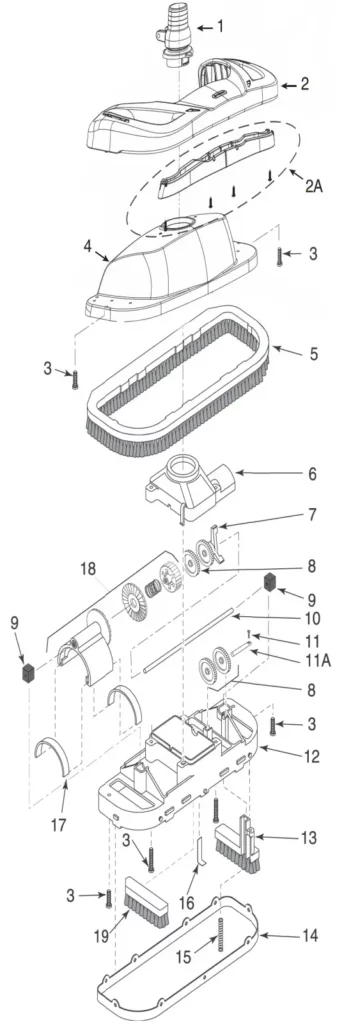

#320 CHLORINE / BROMINE FEEDER PARTS BREAK DOWN DRAWING

*Not used with 2″ PVC, for 1½” PVC only.

**Be sure screen has not come loose in shipment—if loose: Simply snap over 4 posts in bottom of chlorinator to replace.

NOTE: To service check valve F, Remove lockscrew E, and unscrew (counter-clockwise) D chlorinator body from G divertor tee.

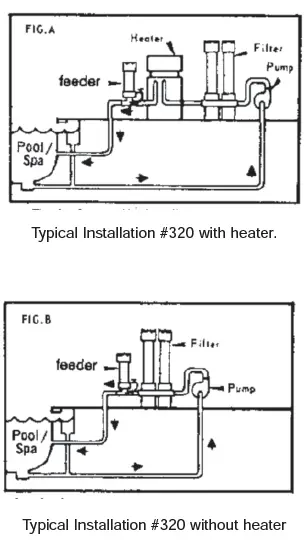

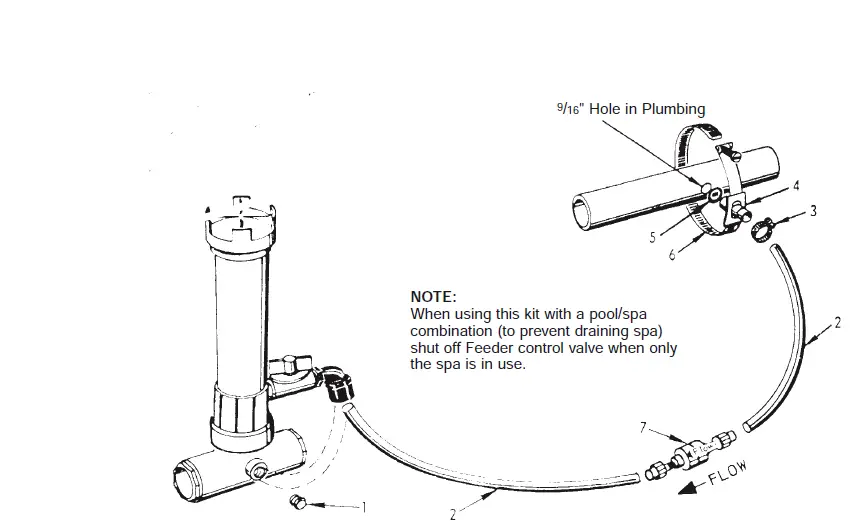

DIRECTIONS

- Turn off pump and timer switches.

- Loosen compression nut and remove Feeder tube and 90° elbow from the diverter tee at base of Feeder.

- Using thread seal tape as thread sealant, wrap ½” MPT plug threads (1) with several turns of the tape only.

Install in place of 90° elbow on diverter tee. - Disconnect another end of Feeder tube from control valve 90° elbow, by loosening the compression nut. Use the compression nuts from old tube to attach new 6′ section (2).

- Push compression nut over tubing end, then push tubing onto tapered end of elbow. Tighten nut firmly by hand.

- Connect another end of plumbing. IF THE POOL/SPA HAS A HEATER, INSTALL IT BETWEEN FILTER AND HEATER. IF YOUR POOL/SPA HAS A SOLAR SYSTEM, INSTALL IT BEFORE SOLAR

SYSTEM INLET LINE. IF NO HEATER, INSTALL IT BETWEEN PUMP AND FILTER. Drill 9/16″ hole in plumbing, remove burrs, and install saddle clamp assembly. (See illustration) Tighten the clamp with a screwdriver. Slide small stainless steel clamp #3 over tubing #2 and slide tubing over saddle tube fitting #4. Secure tubing to fitting by tightening camp with screwdriver. Make sure clamp is below rib at end of saddle tube fitting. - To install ½” CHECK VALVE, cut tube approximately 6″ away from plumbing connection. Remove compression nuts from check valve. Slide nuts over both ends of tube. Insert check valve ends into both pieces of tubing and tighten compression nuts firmly by hand. Be sure arrow “FLOW” is pointing toward the Feeder.

HI FLO FEEDER KIT #R171099 PARTS BREAKDOWN DRAWING

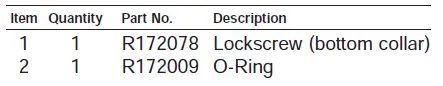

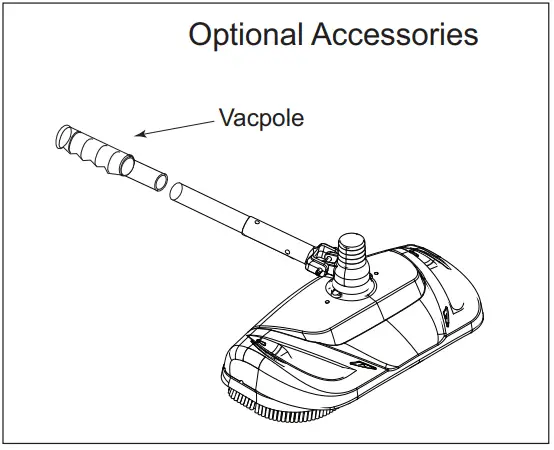

EXTENS IONS

- Going on vacation?

- Need more chlorine?

- Filling Chlorinator/Brominator too frequently?

LIFEGARD CHLORINATOR EXTENSIONS SOLVE THE ABOVE PROBLEMS BY:

- Increasing tablet capacity.

- Larger chamber size allows more erosion of tablets. (See special instructions below)

The 10″ extension doubles and the 20″ extension triples (approximately) the capacity and time between refills. *AVAILABLE THROUGH LIFEGARD DEALERS ONLY.

NOTE: On free standing #300 series chlorinators, the base of the chlorinator should be secured to

prevent the possibility of the chlorinator tipping over due to increased height.

INSTALLATION INSTRUCTIONS

- Follow recharging instructions to the point of filling with tablets

- Making sure O-Ring is clean, lubricated with Lifegard Silicone and in place, screw on extension tightly and secure with lock screw. (You may wish to wait until back in operation before tightening screw to insure against leaks).

- Fill with tablets and continue with normal recharging procedure.

SPECIAL INSTRUCTIONS:

The large chamber size will result in more chlorine being dispensed at the same valve setting, therefore, once installed, several days monitoring will be necessary to readjust chlorinator output.

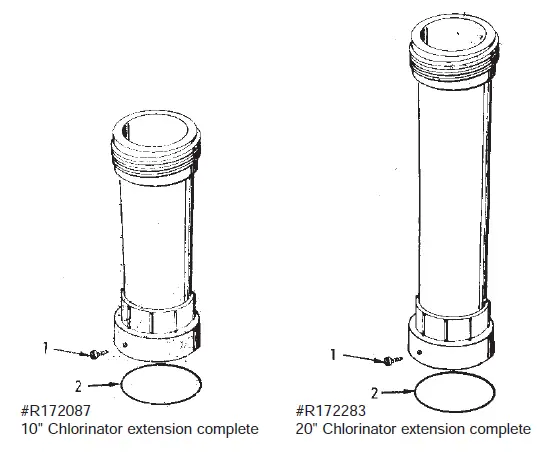

R 172288 1½ ” & 2 ” SLIP SPRING CHECK VALVE

- Special corrosion resistant 1½” & 2″ slip spring check valve can be used

- to check back flow of fluids, air, etc.

- Full free flow design

- Special Spring and Seal for corrosive applications.

- Enclosed spring insuring free operation.

- Very effective when used in conjunction with chlorinator to check back flow

- of chemicals to pool/spa equipment, preventing corrosion problems

- and damage.

- Can be mounted in any position.

Typical check valve installation

NOTE: If heaters are used, a Fireman’s Switch or other safety device must be installed to prevent possible damage and improper operation of Check Valve and other equipment subject to heat damage.

EQUIPMENT SAFETY CAUTION!

PLEASE READ CAREFULLY

Since most pool’s plumbing is not airtight, and a mixture of air and chlorine is highly corrosive to metals, it is important to protect these items from corrosion in the OFF period when no circulation is taking place. (There is no chance for chlorine corrosion when the circulating system is in operation.)

Of course, corrosion or erosion of metal components can still occur independently of any chlorinator installation for the following reasons:

- Water velocity too high.

- Water pH less than 7.2.

- Total alkalinity less than 100 PPM.

If your pool or spa has any of the following equipment, special plumbing procedures must be followed for safe operation:

- Brass or bronze gate, rotary or backwash valves.

- The preceding valves are constructed of PVC or other plastic material with metallic shafts.

- Filters, heaters, heat exchanges or other items with metallic tanks, shafts, coils or tubes.

- NOT FOR USE IN COPPER PLUMBING.

Installation of the OPTIONAL Rainbow #R172288 positive seal, corrosion resistant check valve SHOWN ON REVERSE SIDE will prevent the backflow of corrosive liquids and gases that can damage equipment containing metallic components. Examples listed above.

WARNING: If your pool is equipped with a permanent built in pool-cleaning system, damage could occur to that system if materials are not compatible with low pH Tri-Chloro feeders. Check with the manufacturer for compatibility.

WARNING: Before installing this product, read and follow all warning notices and instructions accompanying this valve. Failure to follow safety warning and instructions can result in severe injury, death, or property damage. Call (800) 831-7133 for additional free copies of these instructions.

IMPORTANT NOTICE!

Attention Installer: This manual contains important information about the installation, operation and safe use of this product. This information should be given to the owner/operator of this equipment.

- The valve must be installed by a qualified serviceman in accordance with the National Electrical Code and all applicable local codes and ordinances.

- Always disconnect power to the equipment at the circuit breaker before servicing any of the equipment. Ensure that the disconnected circuit is locked out or properly tagged so that it cannot be switched on while you are working on the equipment. to do so could result in serious injury or death to servicemen, operator users or others due to electric shock.

- Position the filter and the air relief valve to safely direct water drainage and purged air or water. Water discharged from an improperly positioned filter or valve can create an electrical hazard that can cause severe personal injury as well as damage to property.

For Installation of Electrical Controls at Equipment Pad (ON/OFF Switches, Timers and Automation Load Center)

Install all electrical controls at equipment pad, such as on/off switches, timers, and control systems, etc. to allow the operation (startup, shut-down, or servicing) of any pump or filter so the user does not place any portion of his/her body over or near the pump strainer lid, filter lid or valve closures. This installation should allow the user enough space to stand clear of the filter and pump during system start-up, shut down or servicing of the system filter.

FILTER OPERATES UNDER HIGH PRESSURE.

When any part of the circulating system, (e.g., clamp, pump, filter, valve(s), etc.), is serviced, air can enter the system and become pressurized. Pressurized air can cause the lid to separate which can result in severe injury, death, or property damage. To avoid this potential hazard, follow these instructions:

- Before repositioning valve(s) and before beginning the assembly, disassembly, or adjustment of

the clamp or any other service of the circulating system: (A) Turn the pump OFF and shut OFF any automatic controls to ensure the system is NOT inadvertently started during the servicing; (B) open the manual air relief valve; (C) wait until all pressure is relieved. - Whenever installing the filter clamp FOLLOW THE FILTER CLAMP INSTALLATION INSTRUCTIONS EXACTLY.

- Once service on the circulating system is complete FOLLOW SYSTEM RESTART INSTRUCTIONS EXACTLY.

- Maintain circulation system properly. Replace worn or damaged parts immediately, [e.g., clamp, pressure gauge, valve(s), o-rings, etc].

- Be sure that the filter is properly mounted and positioned according to the instructions provided.

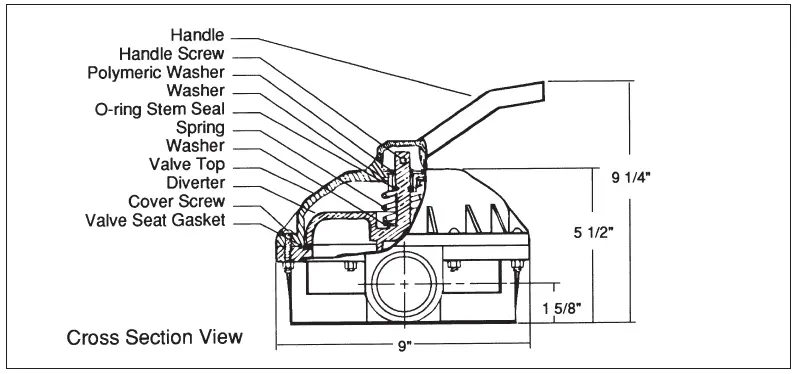

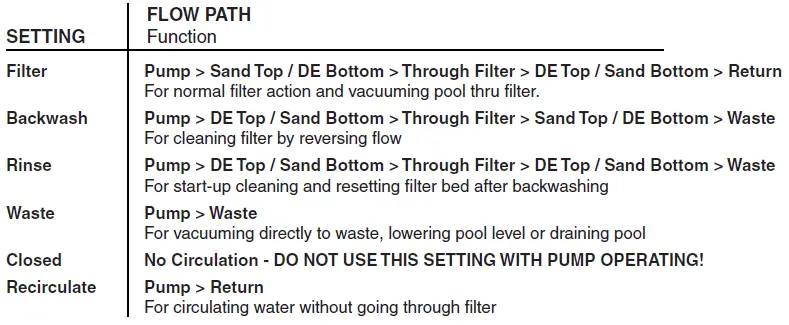

Valve Positions Overview

Valve Installation

This valve is available in two models for use with sand type or diatomaceous earth (DE) type pool filters. Be sure that you have the correct model for your filter. Installing the incorrect model may cause your pump to dead head, or drain the pool when in backwash position.

- Confirm correct valve is being used; DE valves for DE filters and Sand valves for Sand filters.

- Install valve to filter by securing bulkhead nuts on valve to fittings on the filter.

- Plumb pump piping to center pipe in valve.

- Plumb return and waste lines.

Technical Data

Replacement Parts

| Item | P/N | Description | Qty. |

| 1 | 272520 | Handle | 1 |

| 2 | 272405 | Screw – Handle | 1 |

| 3 | 272402 | Washer, Plastic | 1 |

| 4 | 272412 | Valve Top | 1 |

| 5 | 271193 | Washer – 18 GA | 2 |

| 6 | 272400 | Spring – Compression | 1 |

| 7 | 272406 | O-ring – Diverter | 1 |

| 8 | 272413Z | Diverter | 1 |

| 9 | 272409 | Seal -Diverter | 1 |

| 10 | 98211400 | Nut – 1/4″ – 20 Hex | 8 |

| 11 | 272415 | Plat – 2″ Valve Bottom | 1 |

| 12 | 272403 | Screw – 1/4″ – 20 | 8 |

| * | 272422 | Valve Top Assembly | 1 |

*This part number includes items 1 thru 9

Note: When replacing gasket P/N 272409, secure it to valve bottom with an instant cyanocrylate adhesive suitable for bonding rubber to plastic.

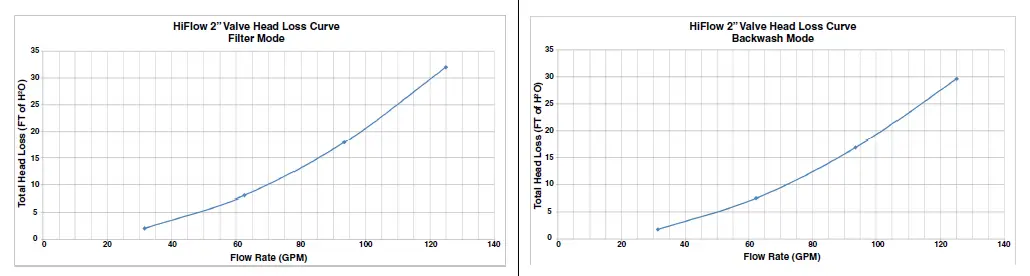

Head Loss Curves

1620 HAWKINS AVE., SANFORD, NC 27330 • (919) 566-8000

10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 • (805) 553-5000

WWW.PENTAIR.COM

All Pentair trademarks and logos are owned by Pentair or one of its global affiliates. Hi-Flow™ is a trademark of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/ or other countries. Unless expressly noted, names and brands of third parties that may be used in this document are not used to indicate an affiliation or endorsement between the owners of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those third parties. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice. Pentair is an equal opportunity employer.

© 2018 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Technical Support

Sanford, North Carolina (8 A.M. to 4:30 P.M.)

Phone: (800) 831-7133

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M.)

Phone: (800) 831-7133 (Ext. 6502)

Fax: (805) 530-0194

Web sites: visit www.pentairpool.com and www.staritepool.com

Related manual: ScreenLogic® Interface User’s Guide (P/N 520493)

FCC Regulatory Safety Notice – This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

FCC Regulatory Safety Notice – This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

- Modifications not expressly approved by the party responsible for FCC compliance could void the user’s authority to operate the equipment.

In this Installation Guide

Use the information in this manual for installing the ScreenLogic® Interface Wireless Connection kit contents.

- For ScreenLogic Interface system operating instructions, refer to the ScreenLogic Interface User’s Guide (P/N 520493)

ScreenLogic® Interface Wireless Connection Kit

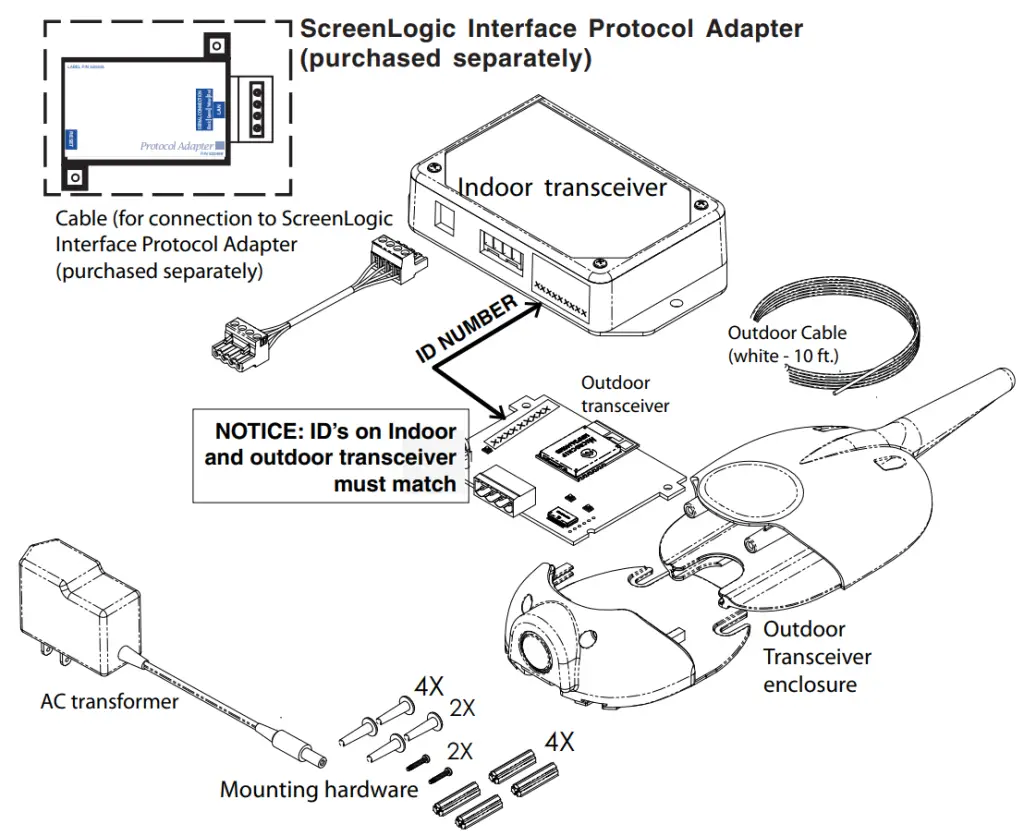

The ScreenLogic® Interface Wireless Connection interface consists of an indoor and outdoor wireless 2.4 GHz transceiver. Note: The transceivers ship from the factory as a matched pair. The ID numbers on each transceiver must be the same number to function correctly. Transceivers are replaced as a matched pair. For more information, call Customer Support (880) 831.7133.

The transceivers provides a wireless connection between the ScreenLogic Interface Protocol adapter and the IntelliTouch® or EasyTouch® Control System Load Center located at the equipment pad. This wireless connection eliminates the existing hard wire connection from inside your home to the equipment pad.

Wireless Connection Kit Contents

The following items are included in the Wireless Connection kit.

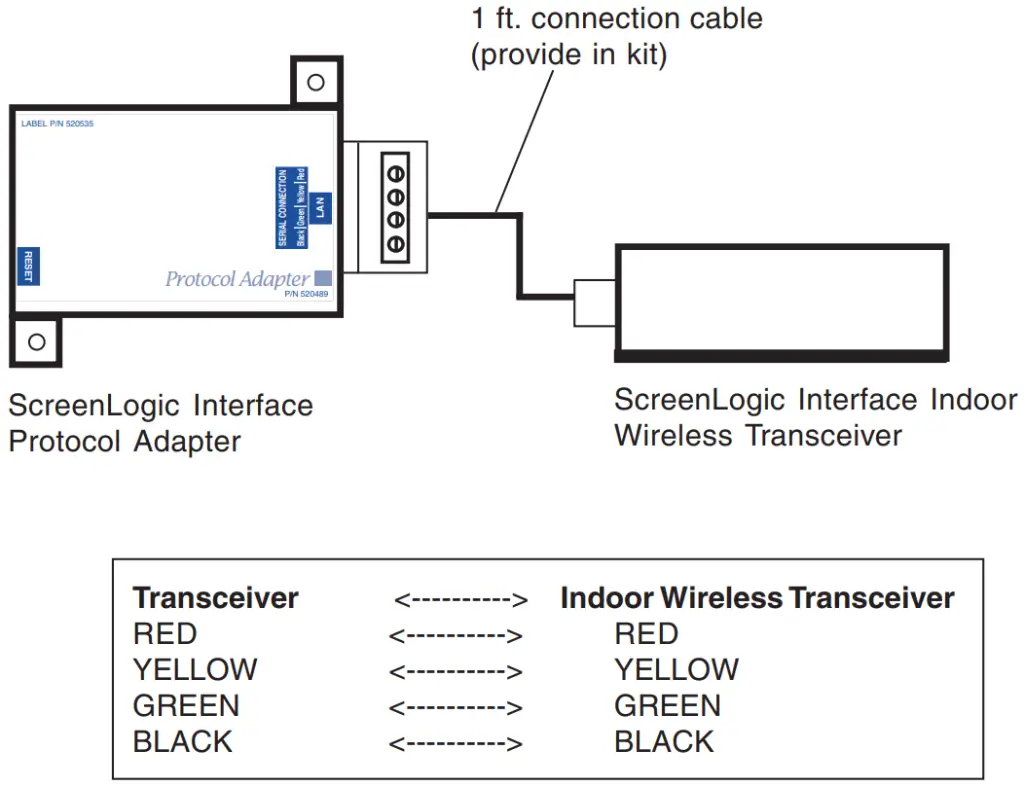

- One ScreenLogic Interface indoor wireless transceiver with AC power adapter and one foot connection cable with attached plugs.

- One ScreenLogic Interface outdoor wireless transceiver with 10 ft. cable, provided in kit with enclosure and mounting hardware.

- ScreenLogic Interface Wireless Connection Installation Guide (this manual)

ScreenLogic Interface Wireless Connection Kit Contents

Summary installation steps

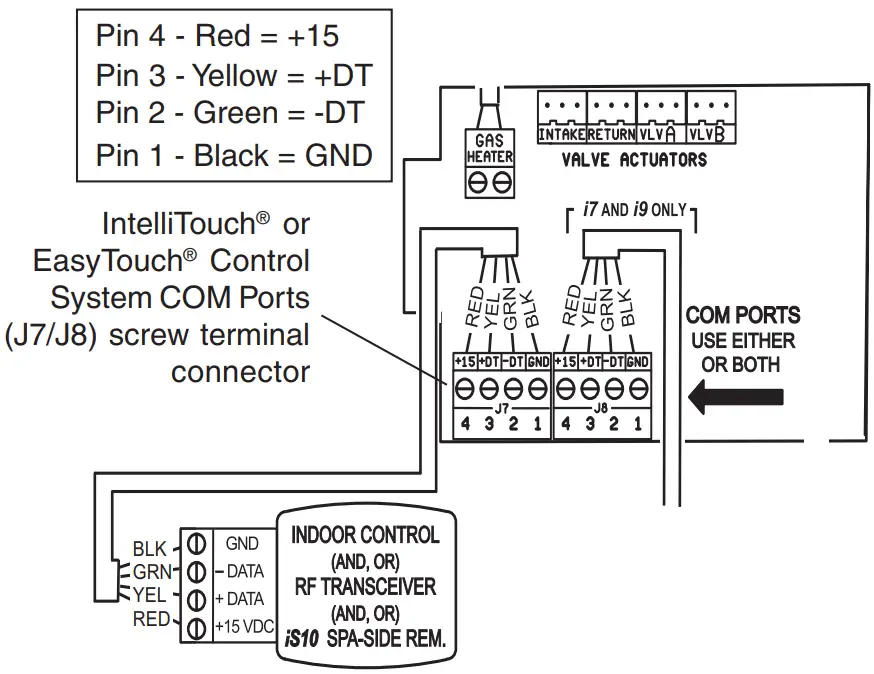

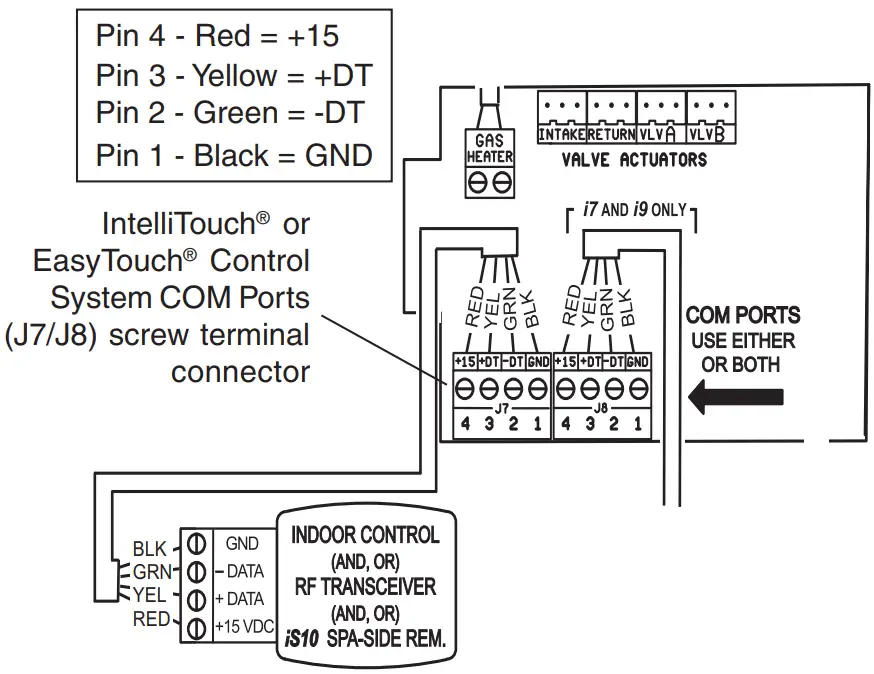

The ScreenLogic® Interface connection diagram on page 2 shows the transceiver locations and connections. To install the ScreenLogic Interface Wireless Connection kit:

- Mount the outdoor transceiver antenna near the IntelliTouch® or EasyTouch® Control System Load Center and connect the transceiver to the COM port connector located in the IntelliTouch® or EasyTouch® Control System Load Center.

- Use the supplied 12 inch cable to connect the ScreenLogic Interface indoor wireless transceiver to the ScreenLogic Interface Protocol adapter. Plug the transceiver AC power adapter into an AC wall-outlet and into the transceiver unit to power up the unit.

ScreenLogic Interface (Indoor Wireless Transceiver)

ScreenLogic® Interface Connection Diagram

Cable distance limits:

– Ethernet cable distance limit = 300 feet

– Four-wire cable distance limit = 1500 feet Note: (*) Optional wiring for existing Indoor Control Panel. Tap into the Indoor Control Panel connector or pig tail off the four-wire cable connected to the Personality board.

Step 1:

Mount the Outdoor Wireless Transceiver and Connect to the IntelliTouch® or EasyTouch® Control System Load Center

The following describes how to mount the transceiver to the IntelliTouch® or EasyTouch® Control System Load Center and connect the four-wire cable to the COM port connector located in the IntelliTouch or EasyTouch Control System Load Center:

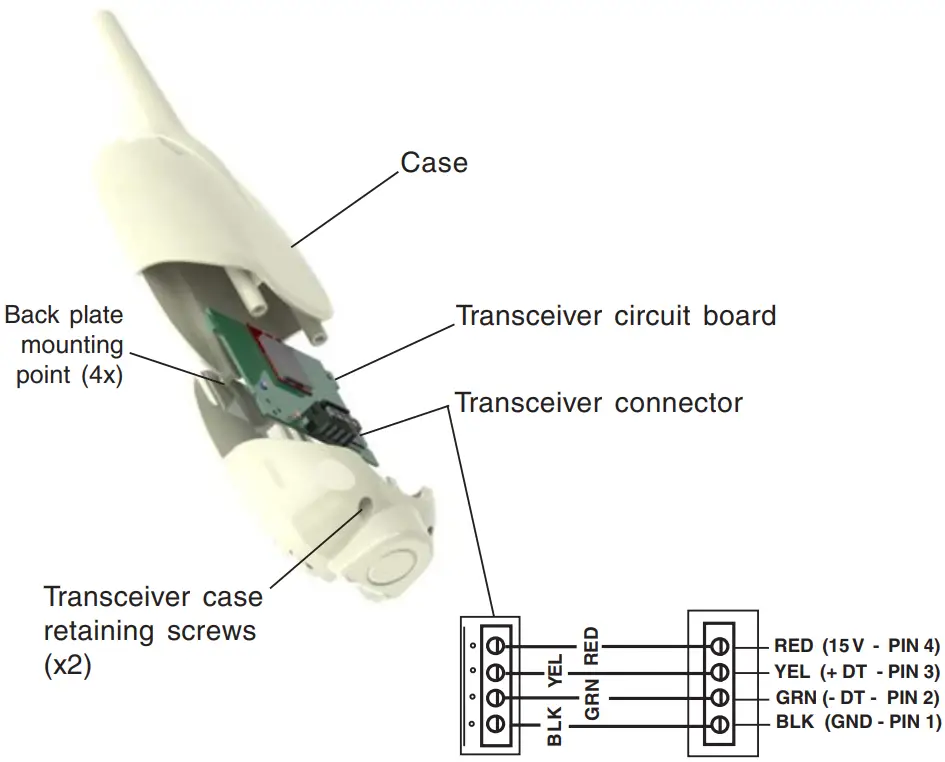

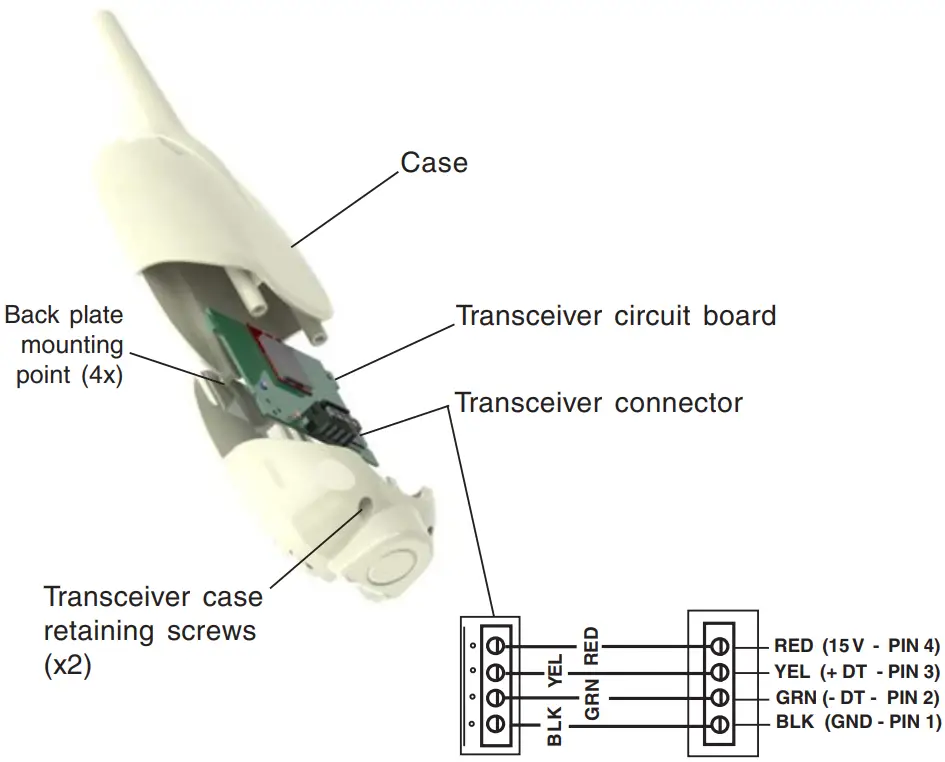

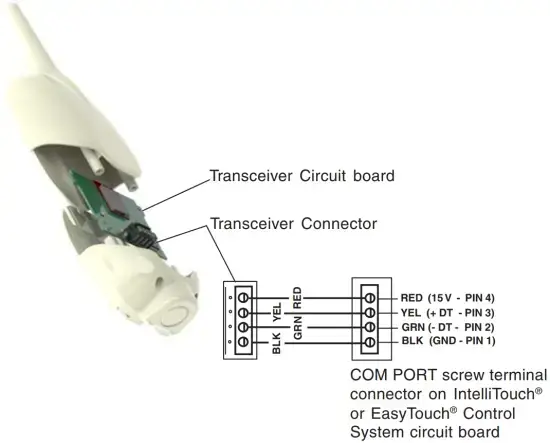

Mount the Transceiver Module

The Transceiver is a two-way radio device with an attached antenna that communicates to and from the IntelliTouch or EasyTouch Control System. Mount the transceiver at a convenient location (on a flat vertical surface) near the load center at a minimum of 5 feet above ground level to optimize the transmit and receive operating range.

- Remove the two retaining screws located on the underside of the transceiver case. Slide the case off the back plate.

- Position the back plate against the mounting surface so that the transceiver is oriented in an upright position with the antenna pointing upwards. Use a pencil to mark the four mounting points. Drill four 3/16 in. diameter holes into the mounting surface and insert the four plastic anchors provided in the kit.

Note: To avoid signal interference, mount the transceiver a minimum of 10 feet away from the load center, any metal surface/structure, or air blower located in the immediate area of the equipment pad. - Position the back plate over the mounting points and secure it with the four mounting screws provided in the kit.

- Carefully position the transceiver circuit board into the mounted back plate. Route the connection wire down through the lower exit hole (left side) at the bottom of the back plate. Carefully pull the wire out the lower hole and position the circuit board in the back plate.

- Position the transceiver circuit board to the left side of the back plate, and slide the case over the circuit board and antenna into the back plate. Secure the circuit board in the case using the two retaining screws.

- Proceed to “Connect the Transceiver connection cable to the COM Port on Control Systems Circuit Board” on the next page.

Transceiver Module Wiring

Connect the Transceiver connection cable to the COM Port on Control System Circuit Board

WARNING Switch OFF the main system power to the Load Center before making any connections.

WARNING Switch OFF the main system power to the Load Center before making any connections.

- Unlatch the enclosure door spring latche(s), and open the door.

- Remove the two retaining screws securing the high voltage cover-panel, and remove it from the enclosure.

- Loosen the two access screws securing the control panel.

IntelliTouch® or EasyTouch® Load Center - Lower down the hinged control panel to access the circuit board.

- Route the four conductor transceiver connection cable into the lower plastic grommet, up through the low voltage raceway to the circuit board.

- Insert the four wires into the screw terminals of the COM PORT plug located on the circuit board as shown on page 6. Using a small flat-blade screwdriver, secure the wires with the screws.

Note: Multiple wires may be inserted into a single screw terminal but increases the chances of a poor or intermittent connection.

Note: Install the ScreenLogic® Interface outdoor wireless transceiver within 10 feet from Load Center

- After the connection has been completed, close the control panel into its original position and secure it with the two access screws.

- Install the front panel and secure it with the two retaining screws.

- Close the Load Center front door. Fasten the spring latche(s).

- Switch the power on to the IntelliTouch® or EasyTouch® Control System Load Center.

- Proceed to the “Connect the ScreenLogic Interface Indoor Wireless Transceiver to the ScreenLogic Interface Protocol Adapter” on page 8.

Step 2:

Connect the ScreenLogic® Interface Indoor Wireless Transceiver to the ScreenLogic Interface Protocol Adapter

To connect the ScreenLogic Interface indoor wireless transceiver to the ScreenLogic Interface Protocol adapter:

- Using the provided connection cable, connect one end of the cable to the ScreenLogic Interface Protocol adapter and the other end to the ScreenLogic Interface indoor wireless transceiver. The cable plugs are keyed for easy connection.

- Plug the ScreenLogic Interface Wireless Connection transceiver AC adapter wall-plug into an AC grounded electrical outlet.

Wiring Configuration

1620 HAWKINS AVE., SANFORD, NC 27330 · (919) 566-8000 10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 · (805) 553-5000

All Pentair trademarks and logos are owned by Pentair, Inc. Pentair Aquatic SystemsTM, ScreenLogic®, EasyTouch® and IntelliTouch® are trademarks and/or registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/ or other countries. iPhone® is a registered trademark of Apple Corporation. Unless expressly noted, names and brands of third parties that may be used in this document are not used to indicate an affiliation or endorsement between the owners of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those third parties. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice. Pentair is an equal opportunity employer.

© 2014 Pentair Aquatic Systems. All rights reserved.

This document is subject to change without notice.

CONTROL INTELLITOUCH® AND EASYTOUCH® CONTROL SYSTEMS FROM YOUR MOBILE DIGITAL DEVICE

Now you can use your iPad®, iPhone® or iPod touch® mobile digital device or Android® device, to control all key functions of your pool or spa, from across the deck or around the globe. New software that communicates with the ScreenLogic interface of your new or existing IntelliTouch or EasyTouch control system is now available as a free download from the App Store® or Google PlayTM. Once it’s installed, you can control everything from pool and spa temperatures to jets, lighting, water features and more–right from your iPhone or other mobile digital device.

No other pool or spa control device offers such convenience.

- Easily turn on your spa and set it to the perfect temperature on your way home from work.

- Control all circuits when you are away–including waterfalls, pool lights, fountains and more.

- Use the History page to monitor temperature, pool/spa, heater and lights from afar.

WE’VE BROUGHT ENERGY SAVINGS WITHIN EASY REACH

The Eco Select® Brand designates eco-friendly products that conserve energy, minimize water usage, reduce noise or otherwise contribute to a more environmentally responsible pool system. As the global leader in pool and spa equipment manufacturing, we stand at the forefront in providing greener choices for our customers. We hope you’ll join us in embracing more eco-friendly poolscapes by choosing Eco Select brand products like this one for your swimming pool.

SCREENLOGIC® INTERFACE FOR MOBILE DIGITAL DEVICES

HERE’S ALL YOU NEED TO DO.

The software for your Apple® mobile digital device or Android® platform is a free download from the Apple App Store® or Google PlayTM. It’s easy to get:

- Using your device, visit the App Store or Google Play.

- Search for “Pentair.”

- Choose to download and install the Pentair® ScreenLogic interface.

FINGERTIP CONVENIENCE, WORLDWIDE CONTROL–FROM YOUR FAVORITE MOBILE DIGITAL DEVICE

How can you manage your pool or spa with our ScreenLogic interface app? Just about any way you want–from just about anywhere.

Easy to navigate. To get started, just choose what you want to manage from a simple home screen.

Temperature control for pool and spa. Getting off work an hour from now? Crank up the temperature on the spa, kick on the pool pump and even choose the heater mode: Solar, Solar Preferred, or Heater. When you arrive, your place of relaxation will be waiting.

Like standing in front of the control panel. If you’ve set up a Waterfall, Jets, or Spillway on your IntelliTouch® or EasyTouch® control system, then those circuits–and any others you’ve similarly chosen–will show up on the Circuits screen of your ScreenLogic interface app. Which means you enjoy push-button control anytime from anywhere.

AVAILABLE FROM:

Know what your pool’s been doing. Your ScreenLogic interface app shows you a visual history of your pool and spa’s operation. See how your water temperatures have changed over time. Confirm the exact periods that the Lights, Heater, Solar, Spa, and Pool modes have been used. Know your wishes are being followed and your money is being saved–no guesswork necessary.

If your pool is equipped with an IntelliTouch or EasyTouch system and a PC or Mac® computer ScreenLogic interface to access them, you’re already good to go.

If you don’t yet enjoy the benefits of an IntelliTouch or EasyTouch system, now’s the ideal time to upgrade to electronic convenience and get mobile digital device remote control at the same time. If you’re an IntelliTouch or EasyTouch system owner, you can gain iPad®, iPhone® and iPod touch® mobile digital device or Android® device access through a PC and Mac computer ScreenLogic Interface and Wireless Connection Kit (Part # 522104). This kit lets you remotely manage your pool and spa through your PC or Mac computer as well as your mobile digital devices.

1620 HAWKINS AVE, SANFORD, NC 27330 800.831.7133 WWW.PENTAIRPOOL.COM

All Pentair trademarks and logos are owned by Pentair or one of its global affiliates. ScreenLogic®, IntelliTouch®, EasyTouch®, and Eco Select® are registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/or other countries. iPad®, iPhone®, iPod touch®, Mac®, Apple® and App Store® are registered trademarks of Apple, Inc. in the United States and/or other countries. Google PlayTM and Android® are trademarks and/or registered trademarks of Google, Inc. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice. Pentair is an equal opportunity employer.

pumps · filters · heaters · heat pumps · automation · lighting · cleaners · sanitizers · water features · maintenance products

1/16 Part # P1-096 ©2016 Pentair Water Pool and Spa, Inc. All rights reserved.

Product Information

The OMNIFILTER QuickConnect Water Filtration System is a

tankless reverse osmosis system designed to provide clean and

purified water. This system is manufactured by Pentair, a trusted

brand in water filtration technology.

Before installing the tankless reverse osmosis system, it is

important to ensure that your water supply meets the following

operating specifications:

- Recommended Feed Pressure Range: [Insert recommended feed

pressure range] - Production Rate (GPD): [Insert production rate]

- Pressure Range: [Insert pressure range]

- Temperature Range: [Insert temperature range]

- Operating Voltage: [Insert operating voltage]

- TDS (Total Dissolved Solids): [Insert maximum TDS]

- Maximum Hardness: [Insert maximum hardness level]

- Sulfide, Iron, and Manganese: [Insert tolerance for sulfide,

iron, and manganese] - Chlorine in Water Supply: [Insert tolerance for chlorine

presence] - pH Limits: [Insert pH limits]

- Overall Dimensions: [Insert dimensions of the system]

- Weight: [Insert weight of the system]

Please note that failure to comply with these operating

specifications may reduce the effectiveness of the system and void

the warranty.

Product Usage Instructions

- Ensure that your water supply meets the operating

specifications mentioned above. - Select an appropriate location for installing the OMNIFILTER

QuickConnect Water Filtration System. It should be near a cold

water supply line and a drain for wastewater. - Shut off the main water supply to your home or building.

- Install the pre-filter cartridge(s) according to the provided

instructions. This step may vary depending on the specific model of

the system. - Connect the system’s inlet valve to the cold water supply line

using the provided fittings. Ensure a secure and leak-free

connection. - Connect the system’s outlet valve to a faucet or dispenser

using the provided fittings. Again, ensure a secure

connection. - Connect the wastewater drain line to a suitable drain. Make

sure it is positioned to prevent any backflow or leaks. - Turn on the main water supply and check for any leaks. If leaks

are detected, immediately shut off the water supply and fix them

before proceeding. - Allow the system to flush for a few minutes to remove any air

or impurities. - Follow the system-specific instructions for turning on and

operating the reverse osmosis filtration process. - Regularly replace the filter cartridges as recommended by the

manufacturer to ensure optimal performance and water quality.

For more detailed installation and operation instructions, refer

to the OMNIFILTER QuickConnect Water Filtration System Tankless

Reverse Osmosis System Installation and Operation Manual provided

by Pentair.

Remember to consult a professional plumber or contact the

manufacturer’s customer support if you encounter any difficulties

during installation or have any questions regarding the product

usage.

View Fullscreen

OMNIFILTER

QUICKCONNECT WATER FILTRATION SYSTEM TANKLESS REVERSE OSMOSIS SYSTEM INSTALLATION AND OPERATION MANUAL

©2022 Pentair Residential Filtration, LLC

pentair.com

IMPORTANT: Before installing this tankless reverse osmosis system, make certain your water supply complies with the following operating specifications. Failure to do so may reduce the effectiveness of the system and will void the warranty.

· Please read all instructions and precautions before installing and using your Tankless Reverse Osmosis system.

· For standard, under-sink installation on 3/8″ (9.52 mm) steel, brass, or copper cold water line.

· When selecting a location of the system, take into consideration the length of tubing required for connections between existing plumbing and system components. Some installation sites may require more tubing than provided in the kit.

· Ensure that the system’s installation location is within 5 feet (1.52 meters) of a 110 volt grounded outlet.

· Numbered diagrams correspond with numbered steps.

SPECIFICATIONS

Recommended Feed Pressure Range: Production Rate (GPD): Pressure Range: Temperature Range: Operating Voltage:

TDS: Maximum Hardness: Sulfide, Iron and Manganese: Chlorine in Water Supply: pH Limits: Overall Dimensions:

Weight:

10 to 60 psi (0.694.14 bar) 396.4 gpd (1500 Lpd) 15 to 100 psi (2.756.89 bar) 40100°F (4.437.8°C) Input Voltage: 100-240V AC Output Voltage: 24V DC <2000 ppm <10 gpg (170 mg/L) <0.01 ppm <2 ppm 311 5.51″ W x 17.60″ D x 17.10″ H (140mm x 447mm x 434mm) 25.35 lbs (11.5 kg)

If the hardness of your water is above 10 gpg (171 mg/L), lime scale will build up rapidly on the membrane. Scale buildup will plug the membrane and make the system ineffective. We do not recommend these tankless reverse osmosis systems be used with water in excess of 10 gpg (171 mg/L) hardness.

A maximum total level of approximately 0.01 ppm sulfide, iron or manganese is permissible. See your local dealer to reduce these substances in your water.

PARTS INCLUDED:

· Main Body Assembly · Power Adapter · Composite Filter (CF) & Carbon Filter (CB) Cartridges · RO Membrane Cartridge (RO) · Inlet Water Adapter · Smart Faucet · 1/4″ Tubing – White · 1/4″ Tubing – Red · 3/8″ Tubing – White · 1/4″ Quick Connect Locking Clip · 3/8″ Quick Connect Locking Clip · 1/4″ Quick Connect Fitting · Drain Line Clamp · Front Cover · Owner’s Manual · Quick Reference Guide

Tools and Materials Required

· Hand or electric drill (cordless preferred) · (2) Adjustable wrenches · Slotted and Phillips screwdrivers · File · Safety glasses · Drill bits: 1/8″, 3/16″, 1/4″, 3/8″ · Tube cutter or utility knife · Pencil · Towel · Bucket If sink does not have hole for separate faucet: · Center punch · 3/4″ hole saw or drill bit · Safety mask

NOTE: All tools may not be necessary for installation. Read installation procedures before starting to determine what tools are necessary.

CALIFORNIA PROPOSITION 65 WARNING

WARNING: This product contains chemicals known to the State of California to cause cancer or birth defects or other reproductive harm.

PRECAUTIONS

GENERAL

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

CAUTION RO System must be protected against freezing,

which can cause cracking of the RO components and water leakage. NOTE:

· Your water must be within required limits for satisfactory operation. If not, your membrane life may be shortened and your warranty will be voided (see Specifications on page 2).

· This tankless reverse osmosis system will not protect against disease-causing bacteria or remove naturallyoccurring harmless bacteria.

· Install on cold water line only. · Make certain that installation complies with all state and

local laws and regulations. · The replacement cartridges and tankless reverse osmosis

element included with this system have limited service lives. Changes in taste, odor, and color of the water being filtered indicate that the cartridge should be replaced. · After prolonged periods of non-use (such as during a vacation) it is recommended that the system be flushed for 5 minutes before it is used. · A drinking water cartridge may contain carbon fines (very fine black powder). After installation, flush the system for 5 minutes to remove the carbon fines before using the water. · It is recommended that you run the tap at least 20 seconds prior to using water for drinking or cooking purposes. · The contaminants or other substances removed or reduced by this water treatment device are not necessarily present in your water.

2 · QUICKCONNECT TANKLESS RO Installation and Operation Manual

HOW REVERSE OSMOSIS WORKS

The Tankless Reverse Osmosis (RO) System uses a semipermeable membrane to reduce dissolved salts and minerals, improving the taste and odor of your water. The RO membrane is made of layers of micron-thin film wound around a hollow center core. Water molecules can pass through the membrane, but dissolved salts and minerals are rejected.

The Tankless Reverse Osmosis System features 3-stage filter action. Your water supply is pre-filtered to reduce dirt and chlorine that may foul the membrane. The RO membrane separates this pre-filtered water into PRODUCT WATER and DRAIN or REJECT WATER. Incoming water pressure forces the product water through the membrane. Dissolved solids and other contaminants cannot pass through the membrane and are sent to the drain as reject water.

For each gallon of water produced, less than 1 gallon of water goes to the drain. When used under the Specifications on page 2 of the manual, your Tankless Reverse Osmosis membranes should last 12-24 months.

INSTALLATION

GROUNDING INSTRUCTIONS: This appliance must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. This appliance is equipped with a cord having an appliance-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the appliancegrounding conductor can result in a risk of electric shock. Check with a qualified electrician or service representative if you are in doubt whether the appliance is properly grounded. Do not modify the plug provided with the appliance; if it will not fit the outlet, have a proper outlet installed by a qualified technician.

A. The power-supply receptacle for the appliance shall be installed in a cabinet or on a wall adjacent to the undercounter space in which the appliance is to be installed;

B. There shall be an opening through the partition between the compartments specified in (A) that is large enough for the attachment plug to pass through. The longest dimension of the opening shall not be more than 1-1/2 in (38 mm);

C. The edges of the opening specified in (B) shall, if the partition is wood, be smooth and rounded, or, if the partition is metal, be covered with an edge protector provided for this purpose by the manufacturer; and

D. Care shall be exercised, when the appliance is installed or removed, to reduce the likelihood of damage to the supply cord.

QUICKCONNECT TANKLESS RO Installation and Operation Manual · 3

INSTALLATION CONTINUED . . .

1. Installing the Water Supply Adapter

1

The supply adapter fits 1/2″-14 NPS supply threads or 3/8″ x 3/8″ compression. If local codes permit, it may be used to connect the system to the cold water supply line. If local codes do not permit the use of the supply adapter, alternate connectors can be obtained from your local supplier.

Directions:

(A) Turn off cold water supply line. If cold water line does not have a shut-off valve under the sink, you should install one.

(B) Turn on the cold water faucet and allow all water to drain from line.

(C) Disconnect riser cold water supply valve.

(D) Ensure the sealing gasket is fully seated into the feed adapter valve female thread.

(E) Install feed adapter valve onto supply valve as desired. The feed adapter valve may be installed at the bottom of the supply hose or the top of the cold water line. Hand tighten only.

(F) Connect the riser to the feed adapter valve.

NOTE: Be careful not to cross-thread.

2. Selecting the Faucet Location

The drinking water faucet should be positioned with function, convenience, and appearance in mind. An adequate flat area is required to allow faucet base to rest securely. The faucet fits through a 3/4″ hole. Most sinks have pre-drilled 1-3/8″ or 1-1/2″ diameter holes that may be used for faucet installation. If these pre-drilled holes cannot be used or are in an inconvenient location, it will be necessary to

drill a 3/4″ hole in the sink to accommodate the faucet.

CAUTION This procedure may generate dusts which can cause severe irritation if

inhaled or come in contact with the eyes. The use of safety glasses and safety mask for this procedure is recommended.

CAUTION DO NOT ATTEMPT TO DRILL THROUGH AN ALL-PORCELAIN SINK. If

you have an all-porcelain sink, mount the faucet in pre-drilled sprayer hole or drill through countertop next to sink.

CAUTION When drilling through a countertop, make sure the area below the

drilled area is free of wiring and piping. Make certain that you have ample room to make the proper connections to the bottom of the faucet.

CAUTION Do not drill through a countertop that is more than 1″ thick.

CAUTION Do not attempt to drill through a tiled, marble, granite or similar

countertop. Consult a plumber or the countertop manufacturer for advice or assistance.

The following instructions apply to stainless steel sinks ONLY.

(A) Line bottom of sink with newspaper to prevent shavings, parts or tools from falling down the drain.

(B) Place masking tape over the area to be drilled to help prevent scratches if drill bit slips.

(C) Mark point with center punch. Use a 1/4″ drill bit to drill a pilot hole through sink.

(D) Use a 1-1/4″ hole saw to enlarge hole. Smooth rough edges with a file.

2

4 · QUICKCONNECT TANKLESS RO Installation and Operation Manual

Pilot Hole

B

C D

1/41″/4″C

11/4″ 11/4″

D

Mounting A

Hole

INSTALLATION CONTINUED . . .

3

3. Mounting the Faucet

NOTE: Not all parts provided with the faucet may be needed for installation.

(A) Slide chrome plate and black rubber washer onto faucet by threading both drain tubes through the holes on the plate and washer.

(B) Attach large diameter white 1/4″ drain tube to barb fitting at the faucet base.

(C) Slide white extension spacer onto long threaded section of faucet. Open end of extension should come in contact with base of faucet.

(D) Screw washer, and locking nut onto end of faucet threads.

(E) Screw quick connector onto end of faucet threads.

(F) Wet end of 1/4″ white tube. Push into bottom of quick connector. Tug gently to be sure connection is complete. Insert 1/4″ quick coupling lock plate between quick connect port and claw of tubing.

NOTE: To remove the tube, push on the fittings’ collar and pull the tube out.

(G) Holding the faucet, feed the tube through the hole in the sink. Position the faucet handle at a desired location.

(H) Center the faucet. Tighten the locking nut with a wrench until it is tight.

4. Installing the Drain Clamp

NOTE: If you have a single-basin sink with a disposal unit, call Technical Support

5

for options.

NOTE: Before installing the drain clamp, check the drainpipes under the sink

B

for corrosion. Corroded pipes should be replaced before continuing with

installation.

(A) Attach the drain clamp to a vertical section of the drainpipe, about 6″ above the trap. Make sure the opening on the drain clamp is facing towards the drinking water faucet.

(B) Using the fitting hole of the drain clamp as a guide, drill a 1/4″ hole through one side of the drainpipe.

(C) Remove the drain clamp from the drainpipe and enlarge the hole with a 3/8″ drill bit. Use a file to remove rough edges from the drilled hole.

5

(D) Make sure the black rubber gasket is adhered to the inside of the drain clamp and place the drain clamp assembly over the drilled hole. Look through the hole and position the clamp so that the center of the clamp hole is slightly higher (about 1/16″) than the center of the drilled hole. Tighten the clamp securely.

(E) Screw the plastic compression nut onto the drain clamp until hand-tight.

5. Connecting the System to the Drain

CAUTION This is a gravity drain line. Any loops, kinks or sharp bends must be

eliminated before proceeding.

(A) Locate the 1/4″ red tubing.

(B) Insert one end of the tubing into the “Drain” port on the back of the system. Insert 1/4″ quick coupling lock plate between the quick coupling and the jack

6

catch of the tubing.

(C) Run the other end of the tubing to the desired drain location.

6. Installing the System

WARNING: When selecting a installation location of the system, take into consideration the length of tubing required for connection between components. Some installation sites may require more tubing than provided in the kit.

(A) Select a location under the sink, or other suitable area where the system will be installed.

NOTE: The system carton can be used to determine the operational footprint required for installation of the system and replacement cartridges.

(Figure 6) Carton is oversized 4-6″ in each direction for packing materials.

(B) The system should be set on a firm, solid surface that is able to support the weight of the system.

Faucet Body Upper Gasket Countertop Gasket Ring Below Gasket Installation Knob Inlet Water Threaded Pipe Direct Quick Coupling 1/4″ Quick Coupling Lock Plate 1/4″ PE Pipe

3/8″ Tube

C

QUICKCONNECT TANKLESS RO Installation and Operation Manual · 5

7

INSTALLATION CONTINUED . . .

7. Connecting the Faucet to the System

(A) Determine the length of plastic white tubing needed to connect from the system to the faucet. Be sure to allow enough tubing to prevent kinking and cut the tubing squarely. Use a marker to mark one end of the tubing 5/8″ from the end. Wet the end of the 1/4″ tube and push into the port on the back of the system labeled “Drinking Faucet”. Insert 1/4″ quick coupling lock plate between quick connect port and claw of tubing.

CAUTION Do not bend or crimp tube while inserting.

(B) Gently pull back on the tube to ensure it is connected properly.

8. Connecting the System to the Water Supply Adapter

(A) Locate remaining length of 3/8″ plastic white tubing.

8

(B) Place a mark on the tubing 5/8″ from the end. Moisten the end of the tubing

with water and insert with a twisting motion push into inlet quick connect

fitting on the back of the system labeled “Inlet”. Insert the 3/8″ quick

coupling lock plate between the quick connect port and the claw of the water

inlet tubing.

(C) Cut the tube to a length that will allow connection to the Water Supply Adapter that was installed in Step 1. Ensure the tubing does not kink. Place the Compression Nut and Compression Sleeve over the Plastic tubing and then place the Insert Fitting into the end of the Tubing. Tighten the Compression Nut onto the Water Supply Adapter.

9. Connecting the Power Adapter

(A) Locate the electrical adapter, and plug the smaller end into the power receptacle on the back of the system.

9

(B) Locate the Faucet power cord and plug into the port titled “Faucet Power” on the back of the system. Screw the movable nut on the aviation connector clockwise until tightened.

10. Filter Installation

(A) Remove filter cartridges from their packaging and remove the rubber stoppers at the top of each cartridge.

(B) The order sequence of the cartridges is as follows: Top: RO Membrane Cartridge Middle: CB Filter Cartridge Bottom: CF Filter Cartridge

(C) Insert filter cartridges with handle parallel to the floor, turn 90° so that the handle is now perpendicular to the floor.

11. System Start-up

10

(A) Connect machine to power supply and plug into electrical outlet. When the machine is first powered on, a small beep will occur and four indicator lights will flash.

(B) The machine will automatically flush for 5 minutes. During this time the water quality indicator light will flash red.

(C) Open faucet and allow to run for 30 minutes. During this time the water quality indicator light will flash with the actual water quality color.

(D) While flushing occurs, check the tightness of all parts and fittings carefully to ensure no leaks at the connection points.

(E) Once flushing is complete, the faucet can now be closed. The machine will enter a normal water production state and the water indicator light will remain on with the actual water quality color.

CAUTION Visually check the entire system for leaks. If a leak is present, see

Troubleshooting on page 8.

NOTE: To complete 24-hour flushing, reference page 9. Flush 24-hours upon start or before first use. For the first 24-hours use water for cooking and/or cleaning.

6 · QUICKCONNECT TANKLESS RO Installation and Operation Manual

Filter Cartridge Replacement

NOTE: The life of the filter cartridges depends on water volume used and the quality of the feed water. It is recommended that the filter cartridges be replaced every 12 months, or when there is a noticeable change in taste, odor, or flow of filtered water.

Ensure the correct cartridge is purchased for the system. Pentair Tankless RO System #4006877 uses the following replacements: #4006882 / ROM-24M / Replacement RO Membrane #4006943 / CF-12M / CB-12M / Replacement Filter 2-Pack

Cartridge Sequence

Cartridge Replacement A. Twist cartridge 90 degrees counter-clockwise and remove

from system. B. Install new cartridge in the proper location, push firmly and

twist clockwise.

Indicator Lights

Indicator Lights · CF: CF Filter Cartridge Lifetime Indicator · RO: RO Membrane Cartridge Lifetime Indicator · CB: CB Filter Cartridge Lifetime Indicator · Water Drop: Water Quality Indicator (TDS indicator)

Smart Faucet Indicator Lights

· To quickly and easily get filter life indication, the Smart Faucet includes an LED ring around the base of the faucet which indicates filter life.

· Blue – Normal, filter life is good · Purple – Needs attention, filter life will expire soon.

Indicator will change when there are 15 days of filter life remaining. · Red – Expired, filter should be changed

Inserting Cartridges into System

Cartridges Fully Engaged in System

Troubleshooting

QUICKCONNECT TANKLESS RO Installation and Operation Manual · 7

Indicator Status

System Error Indications

Error Type Timeout fault

Indicator Lights 3 red indicators flash

Frequent start-stop Water leakage

Low temperature

3 purple indicators flash 4 red indicators flash 3 indicators flash

Filter Cartridge Lifetime Display

Fault Indicator Go out Go out

Red indicators flash Red indicators flash

Recover Method

Power off and then power back on the system

Power off and then power back on the system

Locate and repair water leak

Power off and then power back on the system

Lifetime status

Life Time Left (Days)

Treatment Capacity Remaining

Warning Type

Filter cartridge indicator

Buzzer

Normal Early Warning

Alarming

Greater than 15 days

Greater than 0 and less than 15 days

Zero days

Greater than 150 liters

Continuous Blue light on

No warning reminder

Greater than 0 and less than 15 liters

Zero

Continuous Purple light on Continuous Red light on

Beeps twice during water production (beep 0.3

seconds, stop 1 second)

Beeps during production (beep 0.3 seconds, stop 1

second)

Water Quality Indicator Display

Blue < 100 ppm

TDS LED Color Purple > 100 < 150 ppm

Red > 150 ppm

8 · QUICKCONNECT TANKLESS RO Installation and Operation Manual

Machine Functions

Function

Action logic

Filter Cartridge Indicator

Initial system power on

Beeps 0.1 second, indicator display 3 seconds

Blue-Purple-Red indicator light

First time use washing

Replacement filter flushing

Automatic flushing 5 mins

User turns on the faucet, allows water to flush for 24 hours

NOTE: View To Complete 24-hour Flushing section on the bottom of page 9.

1. CF filter cartridge: turn on the faucet and flush for 5 minutes.

2. RO filter cartridge: turn on the faucet and flush for 30 minutes.

3. CB filter cartridge: turn on the faucet and flush for 15 minutes.

4. Reset the RO filter cartridge together with other filter cartridge: turn on the faucet and flush for 5 minutes, then re-flush for 30 minutes.

5. Reset the CF filter cartridge and CB filter cartridge: turn on the faucet and flush for 15 minutes.

Water production

Water making action

Standby

The machine stops making water and goes into standby mode

Blue light always on

Blue light always on

Light always on (base on filter lifetime

display) Light always on (base on filter lifetime

display)

Fault Indicator Blue-Purple-Red

indicator light Red flashing Flashing according to current water quality status

Water quality indicator light red flashing during

flushing

Light always on according to current

water quality Go out

To reset the filter cartridge: Press and hold the corresponding filter cartridge reset key for 5 seconds. A small beep will sound, the corresponding filter cartridge life indicator will flash purple twice and then turn blue.

To Complete 24-Hour Flushing

A. Within 10 seconds of plugging the system in, press the CF filter button 5 times. You will hear 2 beeps.

NOTE: If the system is already plugged in, unplug the system first and plug it back in to complete this step.

B. Open the faucet and allow water to run for 24-hours. C. Close the faucet. D. Unplug the system and plug it back it. Within 10 seconds

of plugging the system in, press the CF filter button 5 time. You will hear 1 long beep for 3 seconds. E. The system is ready for operation.

QUICKCONNECT TANKLESS RO Installation and Operation Manual · 9

Leaks from tubing fittings

1. Relieve pressure by turning off the water supply to the system and opening faucet until water flow stops. Place a bucket or towel under the system to catch any water drips.

2. Depress collet on system or inlet supply adapter tubing fittings and pull tubing from fitting. Inspect surface of tubing for scratches or debris. Clean or cut back tubing to access clean surface.

3. Wet the end of the inlet tubing and press into the inlet fitting of the system. Ensure the tubing is fully pushed past the fitting O-rings. Place system into operation and check for leaks. If leaks persist, turn off the water supply and contact Technical Support at 1-800-279-9404.

Leaks on quick-connect fittings

1. Close the cold water supply.

2. Depress plastic collar and pull out tubing.

3. Cut off 1″ of tubing and place a mark 5/8″ from end of tubing. Tubing should be cut squarely. The internal and external burrs should be removed.

4. Push tubing 5/8″ into fitting.

5. Open the cold water supply. If leaks persist, call Technical Support.

High TDS in Product Water

If high levels of TDS (Total Dissolved Solids) are detected in your product water as determined by a TDS Monitor, the

cartridge membrane may need to be replaced. See your dealer or plumber to check product water TDS.

Reduced production

Slow or no product water flow usually indicates a clogged cartridge. Replace the CF and CB filter cartridges.

Gradual return of taste and odor

Gradual return of unpleasant taste and odor over a period of time may indicate that your cartridges need to be replaced.

Sudden return of taste and odor

If shortly after complete servicing noticeable taste and odors return, contact Technical Support.

10 · QUICKCONNECT TANKLESS RO Installation and Operation Manual

TANKLESS RO REPLACEMENT PARTS

PART NUMBER

DESCRIPTION

Quantity

Image

4006967

SMART FAUCET

1

4006889

POWER ADAPTER, 120V 60Hz US PLUG

1

4006888

3/8″ PE TUBING, WHITE

60 inches

4006887

1/4″ PE TUBING, WHITE

60 inches

4006886

1/4″ PE TUBING, RED

60 inches

4006882

RO MEMBRANE CARTRIDGE

1

4006943

COMPOSITE AND CARBON FILTERS

1 ea filter (2 total)

For replacement parts, call 800.279.9404 QUICKCONNECT TANKLESS RO Installation and Operation Manual · 11

PERFORMANCE DATA

IMPORTANT: Testing is performed under standard laboratory conditions, actual performance may vary.

Read this performance data and compare the capabilities of this system with your actual water treatment needs. The Tankless RO system contains a replaceable treatment component, critical for the effective reduction of TDS and that product water shall be tested periodically to verify that the system is performing properly.

It is recommended that before installing a water treatment system, you have your water supply tested to determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 58 for the reduction of substances listed below. The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system as specified in NSF/ANSI 58.

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

NOTE: Substances reduced are not necessarily in your water. Filter must be maintained according to manufacturer’s instructions, including replacement of filter cartridges.

The tested efficiency rating for these systems is 54.90%. Efficiency rating means the percentage of the influent water to the system that is available to the user as reverse osmosis treated water under operating conditions that approximate typical daily usage.

The tested recovery rating is 57.50%. Recovery rating means the percentage of the influent water to the membrane portion of the system that is available to the user as reverse osmosis treated water when the system is operated without a storage tank or when the storage tank is bypassed.

MODEL T600R INSTALLED WITH CB-12M, CF-12M, AND ROM-24 CARTRIDGES

Tankless RO Model

Substance

Influent Challenge Reduction

Concentration

Requirements

Standard 58

TotalDissolvedSolids 750 ± 40 mg/L

75%

Average Reduction

96.8%

System tested and certified by NSF International against NSF/ANSI Standard 58 for the reduction of the claim specified on the Performance Data Sheet. C US

This reverse osmosis system contains a replaceable component critical to the efficiency of the system. Replacement of the reverse osmosis component should be with one of identical specifications, as defined by the manufacturer, to ensure the same efficiency and contaminant reduction performance.

12 · QUICKCONNECT TANKLESS RO Installation and Operation Manual

} For Pentair Product Warranties visit:

pentair.com/assets/residentialfiltration-warranty

13845 Bishops Dr. | Suite 200 | Brookfield, WI 53005 | United States P: 262.238.4400 | Customer Service: 800.279.9404 | [email protected] | pentair.com

All indicated Pentair trademarks and logos are property of Pentair. Third party registered trademarks and logos are the property of their respective owners. © 2022 Pentair. All rights reserved.

4006894 REV A DE22

Efficient, dependable filtration for your pool.

The Triton II Filter is the result of over 40 years of product evolution and refinement. It has set the industry standard for effectiveness, efficiency, long runs between service and years of dependable, low-maintenance operation.

The Triton II Filter features a special internal design that keeps the sand bed level, ensuring even water flow and resulting in the most efficient filtration possible.

The best reputation in the industry for all the right reasons.

Besides its filtration performance, the Triton II Filter delivers a level of dependability and ease of operation and maintenance. Every design detail has been refined to make the Triton II Filter the industry standard.

KEY FEATURES

Heavy-duty closure

For easy access with built-in pressure relief valve, making inspection and maintenance faster and easier.

Swing-away water diffuser

Allows instant access to sand and all internal parts.

Combination sand-and-water drain

Speeds servicing and winterizing.

GlasLokTM process one-piece fiberglass-reinforced tank

UV-resistant surface finish for years of dependable, corrosion-resistant, unequaled strength and durability.

Flow system design

Controls filtration quality and helps ensure maximum run times between backwashing to save you time.

Threaded internal parts

For ease of maintenance.

Threaded bulkhead connectors

For easier installation and service.

Time-proven internal design

Ensures that all water receives maximum filtration for crystal-clear results.

SPECIFCIATIONS

| Turnover Capacity–Res. (Gallons) | ||||||||

| Model Number | Filter Area Sq. Ft. | Vertical Clearance* | Filter Diameter | Required Sand** (lbs.) | Flow Rate GPM (Comm.) | 8 hrs. | 10 hrs. | 12 hrs. |

| TR 40 | 1.92 | 32.5″ | 19″ | 175 | 38 | 18,240 | 22,800 | 27,360 |

| TR 50 | 2.46 | 36.75″ | 21″ | 225 | 49 | 23,520 | 29,400 | 35,280 |

| TR 60 | 3.14 | 37.5″ | 24″ | 325 | 63 | 30,240 | 37,800 | 45,360 |

| TR 100 | 4.91 | 41.75″ | 30″ | 600 | 74 | 35,520 | 44,400 | 53,280 |

| TR 140 | 7.06 | 47.25″ | 36″ | 925 | 106 | 50,880 | 63,600 | 76,320 |

* Required clearance to remove the closure.

** Use standard #20 silica sand.

TRADEGRADE

The TradeGrade family of products is exclusively made for and sold by the world’s most demanding pool professionals.

400 Regency Forest Dr | Cary, NC 27518 | United States | 800.831.7133 | www.pentair.com

All indicated Pentair trademarks and logos are property of Pentair. Third party registered and unregistered trademarks and logos are the property of their respective owners. ©2021 Pentair.

All rights reserved.

www.pentair.com

DORADO™

AUTOMATIC POOL CLEANER

INSTALLATION AND USER’S GUIDE

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

![]() Important Notice:

Important Notice:

Attention Installer: This guide contains important information about the installation, operation, and safe use of this product. This information should be given to the owner and/or operator of this equipment after the installation of the pool cleaner.

Attention User: This manual contains important information that will help you in operating and maintaining this pool cleaner. Please retain it for future reference. Consult Pentair with any questions regarding this equipment.

WARNING: Before installing this product, read and follow all warning notices and instructions which are included. Failure to follow safety warnings and instructions can result in severe injury, death, or property damage. Call (800) 831-7133 for additional free copies of these instructions.

WARNING: Before installing this product, read and follow all warning notices and instructions which are included. Failure to follow safety warnings and instructions can result in severe injury, death, or property damage. Call (800) 831-7133 for additional free copies of these instructions.

Consumer Information and Safety

This pool cleaner is designed and manufactured to provide many years of safe and reliable service when installed, operated, and maintained according to the information in this manual. Throughout the manual, safety warnings and cautions are identified by the “  ” symbol. Be sure to read and comply with all of the warnings and cautions.

” symbol. Be sure to read and comply with all of the warnings and cautions.

WARNING: HAZARDOUS SUCTION.

WARNING: HAZARDOUS SUCTION.

![]() Do not play with cleaner or hose or apply to body. Can trap and tear hair or body parts. The hose can trip or entangle swimmers which could result in drowning.

Do not play with cleaner or hose or apply to body. Can trap and tear hair or body parts. The hose can trip or entangle swimmers which could result in drowning.

WARNING:

WARNING:

![]() SUCTION ENTRAPMENT, INJURY, AND DROWNING HAZARD. If your pool has a dedicated suction port (“vac port”) for vacuuming or for an automatic pool cleaner, it must be covered when not in use. A spring-loaded safety cover (a “vac port fitting”) is included with your cleaner. Install it on the suction port to prevent entrapment and injury. If the cover provided does not fit, purchase one that does from your local pool store and install it instead. The cover should conform to IAPMO SPS4-99A.

SUCTION ENTRAPMENT, INJURY, AND DROWNING HAZARD. If your pool has a dedicated suction port (“vac port”) for vacuuming or for an automatic pool cleaner, it must be covered when not in use. A spring-loaded safety cover (a “vac port fitting”) is included with your cleaner. Install it on the suction port to prevent entrapment and injury. If the cover provided does not fit, purchase one that does from your local pool store and install it instead. The cover should conform to IAPMO SPS4-99A.

WARNING: Stop pump before attempting to clean unit. Do not allow swimmers in the pool while the pool cleaner is operating.

WARNING: Stop pump before attempting to clean unit. Do not allow swimmers in the pool while the pool cleaner is operating.

WARNING: To reduce the risk of injury, do not let children use or play with the pool cleaner.

WARNING: To reduce the risk of injury, do not let children use or play with the pool cleaner.

WARNING: Do not allow swimmers in the pool while the pool cleaner is operating. The hose can trip or entangle swimmers which could result in drowning.

WARNING: Do not allow swimmers in the pool while the pool cleaner is operating. The hose can trip or entangle swimmers which could result in drowning.

CAUTION: Moving parts may injure hands or fingers. Stop pump before attempting to clean out pool cleaner head.

CAUTION: Moving parts may injure hands or fingers. Stop pump before attempting to clean out pool cleaner head.

General Installation Information

Pre-Installation Check List

Before installing your cleaner, review and understand all warnings and safety information in this guide. Failure to follow these instructions or improper installation of the cleaner can result in damage to the pool finish or the vinyl liner, Most cleaners are not designed to traverse from floor to wall when the pool cove is 90%. There may be other structures installed in the pool that the cleaner cannot navigate, BE AWARE and supervise the cleaner during unique conditions. Pentair Water Pool and Spa, Inc. disclaim any liability for repairs or replacement to any of these structures or components of the customer’s pool.

Before installing the cleaner in a vinyl liner pool:

Check the liner closely for signs of deterioration or damage from age, chemicals, pool wall damage, etc. If any damage is found, have a qualified pool professional make all the necessary repairs. Also, if there are stones, roots, etc., under the liner, remove them before installing the cleaner.

Before installing the cleaner in a gunite pool or a pool that is partially or completely tiled:

Make sure the pool finish is in proper condition as staining, etching, cracking or delaminating may worsen.

Repair loose tiles and tighten any loose light rings.

Before installing the cleaner, clean your filter system:

Make sure you have cleaned the filter, including backwashing, rinsing, and emptying all baskets. A clean system is necessary for proper cleaner operation and coverage.

Before installing the cleaner, understand cleaner coverage:

The cleaner is designed to rid your pool of debris in approximately 4-6 hours. Less time could be needed, depending on the pool size. The cleaner was not designed to automatically clean steps or swim outs or to work under a solar cover. The cleaner may get stuck in these areas which can result in damage to the pool finish or vinyl liner. Pentair Water Pool and Spa, Inc. disclaim any liability for repairs or replacement to any of these structures or components of the consumer’s pool. It was also not designed to do the initial cleanup for a new pool or when opening your pool for the season.

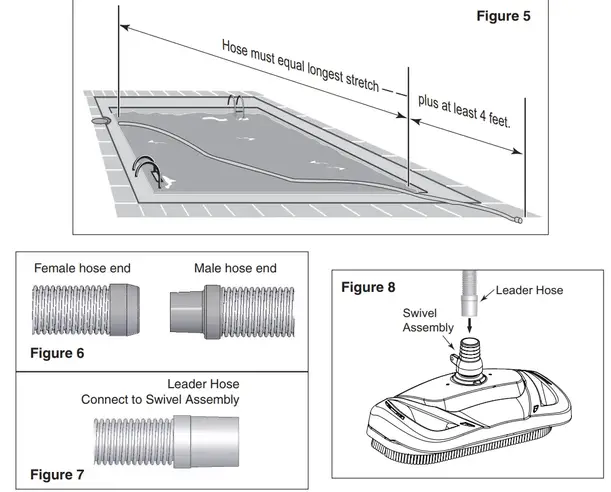

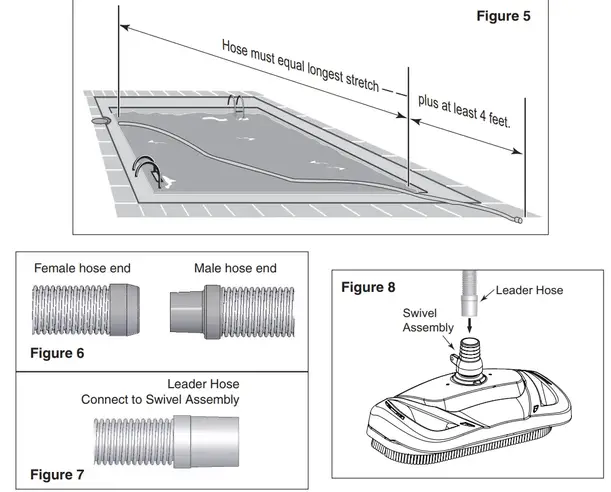

AFTER installing the cleaner, make sure the cleaner is operating correctly: